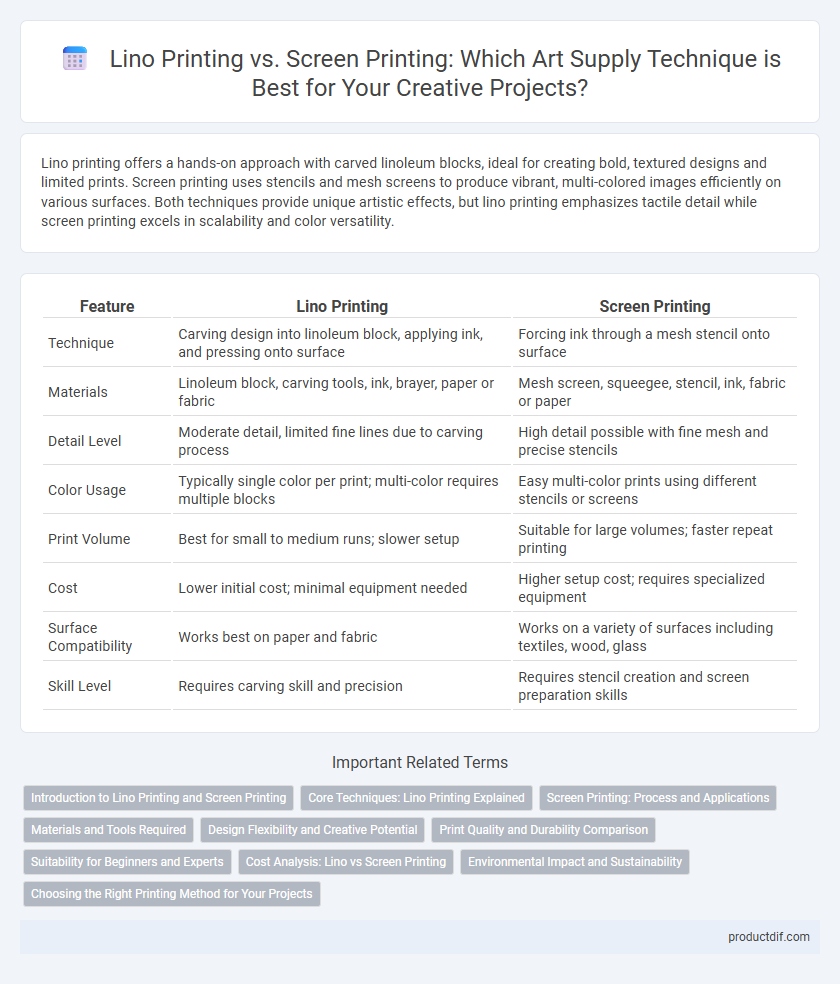

Lino printing offers a hands-on approach with carved linoleum blocks, ideal for creating bold, textured designs and limited prints. Screen printing uses stencils and mesh screens to produce vibrant, multi-colored images efficiently on various surfaces. Both techniques provide unique artistic effects, but lino printing emphasizes tactile detail while screen printing excels in scalability and color versatility.

Table of Comparison

| Feature | Lino Printing | Screen Printing |

|---|---|---|

| Technique | Carving design into linoleum block, applying ink, and pressing onto surface | Forcing ink through a mesh stencil onto surface |

| Materials | Linoleum block, carving tools, ink, brayer, paper or fabric | Mesh screen, squeegee, stencil, ink, fabric or paper |

| Detail Level | Moderate detail, limited fine lines due to carving process | High detail possible with fine mesh and precise stencils |

| Color Usage | Typically single color per print; multi-color requires multiple blocks | Easy multi-color prints using different stencils or screens |

| Print Volume | Best for small to medium runs; slower setup | Suitable for large volumes; faster repeat printing |

| Cost | Lower initial cost; minimal equipment needed | Higher setup cost; requires specialized equipment |

| Surface Compatibility | Works best on paper and fabric | Works on a variety of surfaces including textiles, wood, glass |

| Skill Level | Requires carving skill and precision | Requires stencil creation and screen preparation skills |

Introduction to Lino Printing and Screen Printing

Lino printing involves carving a design into a linoleum block, applying ink to the raised surface, and pressing it onto paper or fabric, making it ideal for bold, textured prints. Screen printing uses a mesh screen to transfer ink through stencil openings, allowing for vibrant, multi-colored designs on various materials. Both techniques offer unique artistic possibilities, with lino printing favoring tactile detail and screen printing excelling in color layering and precision.

Core Techniques: Lino Printing Explained

Lino printing involves carving a design into a linoleum sheet, which acts as a relief surface for inking and pressing onto paper or fabric. This technique requires precision in cutting tools and careful inking to ensure clean, bold prints with distinct texture. The method is favored for its ability to produce sharp contrasts and intricate details in small to medium editions of artwork.

Screen Printing: Process and Applications

Screen printing involves pressing ink through a stenciled mesh screen to create vibrant, durable designs on various surfaces such as fabric, paper, and plastic. This technique allows for precise color layering and is widely used in producing posters, textiles, and custom apparel due to its versatility and high-quality finish. Advanced screen printing often incorporates multiple screens for complex images, making it ideal for mass production and detailed artwork replication.

Materials and Tools Required

Lino printing requires a linoleum block, carving tools, a roller (brayer), and oil-based or water-based inks specifically designed for relief printing. Screen printing involves a mesh screen, a squeegee, photo emulsion, stencil materials, and plastisol or water-based inks suitable for pushing through the screen. Both techniques demand different substrates, with lino printing working best on paper and screen printing often used on textiles and various surfaces.

Design Flexibility and Creative Potential

Lino printing offers high design flexibility through hand-carved blocks, allowing for intricate textures and unique, tactile details that vary with each print. Screen printing excels in creative potential by enabling multi-layered, vibrant color applications and precise replication of complex designs across diverse materials. Artists often choose lino printing for its organic, handcrafted appeal, while screen printing suits projects requiring bold, consistent imagery and extensive color palettes.

Print Quality and Durability Comparison

Lino printing produces crisp, textured prints with a distinctive handcrafted feel, offering excellent durability due to the depth of ink embedded in the carved linoleum blocks. Screen printing yields vibrant, smooth results with fine detail and allows for multiple layers of ink, resulting in highly durable prints resistant to fading and cracking over time. Both methods provide strong print quality and longevity, but screen printing generally excels in detail precision and endurance on various materials.

Suitability for Beginners and Experts

Lino printing offers an accessible entry point for beginners due to its straightforward carving and printing techniques, requiring minimal equipment and lower costs. Screen printing suits both beginners and experts but demands more preparation, such as stencil creation and mesh setup, making it ideal for detailed, multi-color projects and professional-grade prints. Experts benefit from screen printing's versatility and precision, while beginners can quickly grasp lino printing's hands-on, tactile process.

Cost Analysis: Lino vs Screen Printing

Lino printing offers a lower initial investment, as tools like gouges and lino sheets typically cost less than the setup requirements for screen printing, which includes frames, mesh, and emulsion. However, screen printing becomes more cost-effective for larger print runs due to its faster production speed and reusable screens, reducing per-unit expenses over time. Artists and businesses must balance upfront costs with volume needs when choosing between lino and screen printing for budget efficiency.

Environmental Impact and Sustainability

Lino printing uses biodegradable materials like linoleum and water-based inks, resulting in lower environmental impact compared to screen printing, which often involves synthetic screens and plastisol inks that contribute to chemical waste. The sustainability of lino printing is enhanced by its minimal water consumption and the ability to recycle lino scraps, while screen printing generates more non-recyclable waste and consumes larger volumes of water and energy. Choosing lino printing supports eco-friendly art practices by reducing toxic residue and promoting renewable resources.

Choosing the Right Printing Method for Your Projects

Lino printing offers precise, hand-carved designs ideal for small-scale or detailed artwork, making it perfect for artists seeking textured, tactile prints. Screen printing excels in producing vibrant, consistent colors across various materials, suited for large runs and commercial projects. Selecting the right method depends on project scale, desired detail, color complexity, and print durability requirements.

Lino Printing vs Screen Printing Infographic

productdif.com

productdif.com