Steel drums offer superior durability and heat resistance, making them ideal for heavy-duty laundry appliances. Plastic drums provide quieter operation and reduce the risk of fabric damage due to their smoother surfaces. Choosing between steel and plastic drums depends on the priority of longevity versus gentle care in appliance performance.

Table of Comparison

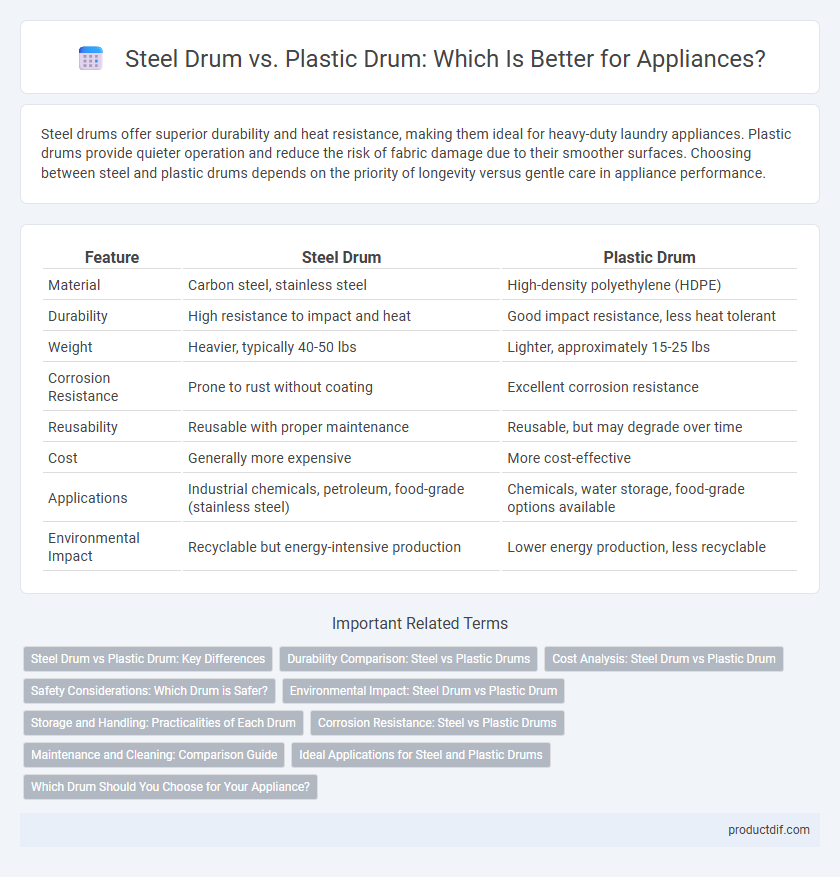

| Feature | Steel Drum | Plastic Drum |

|---|---|---|

| Material | Carbon steel, stainless steel | High-density polyethylene (HDPE) |

| Durability | High resistance to impact and heat | Good impact resistance, less heat tolerant |

| Weight | Heavier, typically 40-50 lbs | Lighter, approximately 15-25 lbs |

| Corrosion Resistance | Prone to rust without coating | Excellent corrosion resistance |

| Reusability | Reusable with proper maintenance | Reusable, but may degrade over time |

| Cost | Generally more expensive | More cost-effective |

| Applications | Industrial chemicals, petroleum, food-grade (stainless steel) | Chemicals, water storage, food-grade options available |

| Environmental Impact | Recyclable but energy-intensive production | Lower energy production, less recyclable |

Steel Drum vs Plastic Drum: Key Differences

Steel drums offer superior durability and resistance to high temperatures, making them ideal for heavy-duty appliance parts and long-term storage. Plastic drums are lightweight, corrosion-resistant, and more cost-effective, suitable for transporting liquids and chemicals in appliances that require less structural strength. Choosing between steel and plastic drums depends on factors like usage environment, load capacity, and chemical compatibility.

Durability Comparison: Steel vs Plastic Drums

Steel drums offer superior durability compared to plastic drums, with enhanced resistance to impact, high temperatures, and harsh chemicals, making them ideal for heavy-duty industrial use. Plastic drums, while lighter and corrosion-resistant, are more prone to cracking and UV degradation over time, limiting their lifespan in demanding environments. The choice between steel and plastic drums depends primarily on the required durability and environmental conditions of the application.

Cost Analysis: Steel Drum vs Plastic Drum

Steel drums generally have higher upfront costs compared to plastic drums due to the expense of raw materials and manufacturing processes. Plastic drums offer lower initial investment and reduced maintenance expenses, making them cost-effective for short-term or lighter-duty applications. Over time, steel drums provide better durability and reusability, which can result in lower total cost of ownership for long-term or heavy-duty use.

Safety Considerations: Which Drum is Safer?

Steel drums offer superior durability and resistance to punctures and high temperatures, making them safer for storing hazardous materials. Plastic drums, while lightweight and resistant to corrosion, are prone to cracking under extreme conditions, potentially leading to leaks. For applications requiring maximum safety, steel drums are generally preferred due to their robust structural integrity and fire resistance.

Environmental Impact: Steel Drum vs Plastic Drum

Steel drums offer greater recyclability and durability, reducing waste and lowering environmental impact over multiple uses compared to plastic drums. Plastic drums, while lighter and resistant to corrosion, contribute to long-term pollution due to slower biodegradation and challenges in recycling processes. Choosing steel drums supports sustainability goals by minimizing landfill accumulation and promoting circular resource use.

Storage and Handling: Practicalities of Each Drum

Steel drums offer superior durability and resistance to punctures, making them ideal for heavy-duty storage and transportation of hazardous or industrial materials. Plastic drums provide lightweight versatility and excellent chemical resistance, simplifying handling and reducing spill risks in environments requiring corrosion protection. Both drum types require specific storage conditions to maintain integrity, with steel drums necessitating rust prevention and plastic drums needing UV protection to avoid degradation.

Corrosion Resistance: Steel vs Plastic Drums

Plastic drums offer superior corrosion resistance compared to steel drums as they are inherently resistant to rust and chemical degradation, making them ideal for storing corrosive substances. Steel drums require protective coatings or linings to prevent rust and corrosion, especially in harsh or humid environments. Choosing plastic drums can reduce maintenance costs and extend container lifespan when handling aggressive chemicals or moisture-prone conditions.

Maintenance and Cleaning: Comparison Guide

Steel drums offer superior durability and resistance to scratches and dents, making them easier to clean and maintain over time compared to plastic drums. Plastic drums are more prone to retaining stains and odors but are lightweight and resistant to corrosion, requiring gentler cleaning methods to avoid surface damage. Regular maintenance of steel drums involves simple wiping and occasional polishing, while plastic drums benefit from mild detergents and thorough rinsing to prevent buildup.

Ideal Applications for Steel and Plastic Drums

Steel drums are ideal for transporting hazardous materials, chemicals, and heavy liquids due to their durability, resistance to impact, and ability to withstand high temperatures. Plastic drums excel in storing food-grade products, pharmaceuticals, and corrosive substances because of their chemical resistance, lightweight nature, and ease of handling. Selecting between steel and plastic drums depends largely on the specific requirements of safety, chemical compatibility, and environmental conditions in industrial and commercial applications.

Which Drum Should You Choose for Your Appliance?

Steel drums offer superior durability and temperature resistance, making them ideal for heavy-duty appliances and environments requiring robust protection. Plastic drums provide lightweight, corrosion-resistant options suited for appliances with less demanding storage needs or where chemical compatibility is crucial. Selecting between steel and plastic drums depends on appliance usage, storage conditions, and material compatibility requirements.

Steel Drum vs Plastic Drum Infographic

productdif.com

productdif.com