Reciprocating compressors use pistons driven by a crankshaft to compress refrigerant, offering high pressure and efficiency for larger appliances but with more noise and vibration. Rotary compressors, featuring a rotating drum or blades, provide quieter operation and smoother performance ideal for compact or residential appliances while typically consuming less energy. Choosing between these compressors depends on factors like appliance size, noise tolerance, energy efficiency, and maintenance requirements.

Table of Comparison

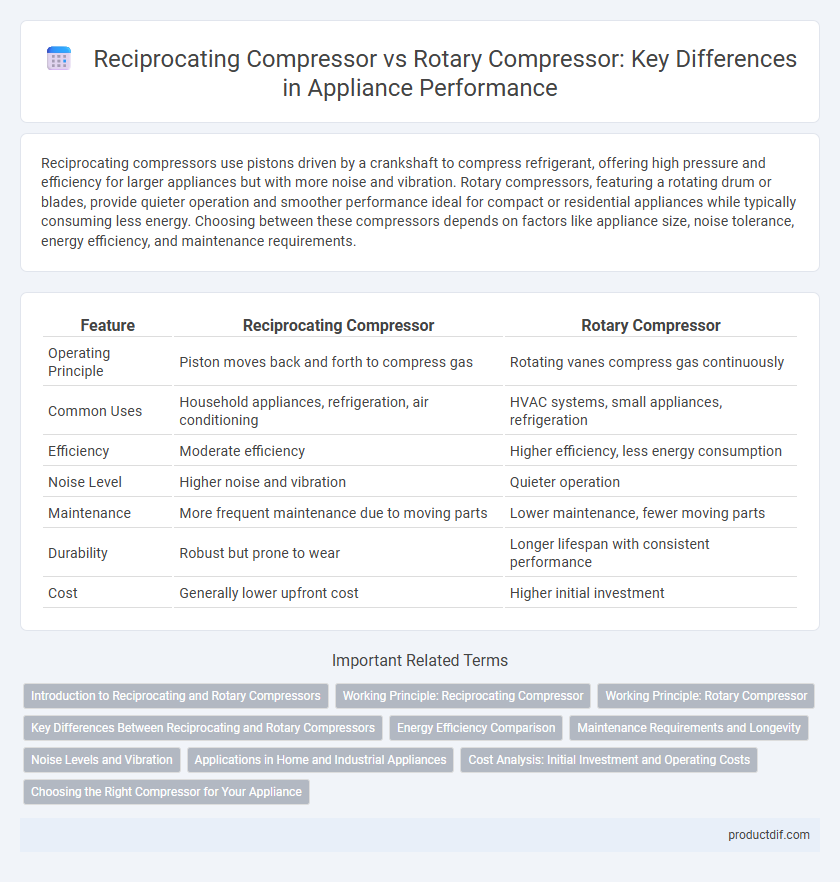

| Feature | Reciprocating Compressor | Rotary Compressor |

|---|---|---|

| Operating Principle | Piston moves back and forth to compress gas | Rotating vanes compress gas continuously |

| Common Uses | Household appliances, refrigeration, air conditioning | HVAC systems, small appliances, refrigeration |

| Efficiency | Moderate efficiency | Higher efficiency, less energy consumption |

| Noise Level | Higher noise and vibration | Quieter operation |

| Maintenance | More frequent maintenance due to moving parts | Lower maintenance, fewer moving parts |

| Durability | Robust but prone to wear | Longer lifespan with consistent performance |

| Cost | Generally lower upfront cost | Higher initial investment |

Introduction to Reciprocating and Rotary Compressors

Reciprocating compressors use pistons driven by a crankshaft to compress gas in a cylinder, offering high-pressure output ideal for refrigeration and air conditioning systems. Rotary compressors, including scroll and screw types, compress gas by continuous rotation of helical screws or scrolls, providing smooth, efficient operation with fewer moving parts. Both compressor types are essential in household and industrial appliances, balancing factors like energy efficiency, noise level, and maintenance needs.

Working Principle: Reciprocating Compressor

Reciprocating compressors operate using a piston driven by a crankshaft within a cylinder, compressing gas by reducing the volume inside the cylinder chamber. As the piston moves down, it creates a vacuum that draws in gas through an intake valve, and on the upward stroke, the compressed gas is expelled through a discharge valve. This positive displacement mechanism delivers high-pressure output ideal for applications requiring intermittent gas flow and precise pressure control.

Working Principle: Rotary Compressor

A rotary compressor operates by using a rotating mechanism, such as a roller or a vane, that compresses refrigerant gas within a cylindrical chamber, reducing its volume and increasing pressure. The continuous rotation ensures a smooth and steady flow of compressed gas, resulting in quieter operation and higher efficiency compared to reciprocating compressors. Commonly found in air conditioners and refrigerators, rotary compressors provide reliable performance with fewer moving parts and reduced vibration.

Key Differences Between Reciprocating and Rotary Compressors

Reciprocating compressors use pistons driven by a crankshaft to compress air, offering high-pressure output and precise control suitable for varied applications, while rotary compressors utilize rotating elements like screws or vanes for continuous, smooth airflow with lower noise and vibration levels. Reciprocating models excel in intermittent, high-pressure tasks but are generally bulkier and require more maintenance, whereas rotary compressors deliver efficient, consistent performance ideal for continuous operation in appliances. The choice depends on factors such as pressure requirements, duty cycle, noise tolerance, and maintenance capacity.

Energy Efficiency Comparison

Reciprocating compressors typically offer higher energy efficiency in low to medium capacity applications due to their ability to maintain consistent pressure ratios and reduced leakage. Rotary compressors, while generally more compact and quieter, often consume more energy under variable load conditions because of internal friction and less precise compression cycles. Energy efficiency depends on application scale and operational demand, making reciprocating compressors preferable for energy-conscious appliance designs requiring frequent startups and shutdowns.

Maintenance Requirements and Longevity

Reciprocating compressors demand frequent maintenance due to their numerous moving parts, including piston rings and valves, which are prone to wear and tear over time. Rotary compressors feature fewer moving components, resulting in lower maintenance needs and generally longer operational life under typical appliance conditions. Longevity in reciprocating compressors is often shorter because of mechanical complexity, whereas rotary compressors benefit from simpler mechanics that enhance durability and reduce downtime.

Noise Levels and Vibration

Reciprocating compressors typically generate higher noise levels and increased vibration due to their piston-driven mechanism, making them less suitable for environments requiring quiet operation. Rotary compressors operate with smoother, continuous motion, resulting in significantly reduced noise and vibration, enhancing user comfort in residential and commercial appliances. Noise reduction technologies in rotary compressors further minimize operational disturbances, offering a quieter and more efficient cooling solution.

Applications in Home and Industrial Appliances

Reciprocating compressors are widely used in home appliances such as refrigerators and air conditioners due to their ability to achieve high pressure with efficient cooling cycles. Rotary compressors, favored in industrial applications, provide smoother and quieter operation with continuous flow, making them ideal for large-scale HVAC systems and refrigeration units. The choice between these compressors depends on the application's demand for pressure, noise levels, and operational efficiency.

Cost Analysis: Initial Investment and Operating Costs

Reciprocating compressors typically have higher initial investment costs due to their complex design and robust components, making them more expensive upfront compared to rotary compressors. Operating costs for reciprocating compressors are generally higher because of increased maintenance requirements and greater energy consumption during operation. Rotary compressors offer lower initial purchase prices and reduced operating expenses, benefiting from simpler mechanics and better energy efficiency in continuous-duty applications.

Choosing the Right Compressor for Your Appliance

Choosing the right compressor for your appliance depends on efficiency, noise level, and application type. Reciprocating compressors offer higher pressure and durability, making them ideal for heavy-duty refrigeration units, while rotary compressors provide smoother operation and lower noise suited for compact household appliances. Understanding these performance differences ensures optimal energy use and appliance longevity.

Reciprocating Compressor vs Rotary Compressor Infographic

productdif.com

productdif.com