Inverter compressors adjust their speed to match cooling demands, resulting in energy savings and quieter operation compared to standard compressors, which run at a fixed speed. This technology enhances appliance efficiency, extends lifespan, and maintains consistent temperature control. Consumers seeking cost-effective and eco-friendly appliances benefit from choosing models with inverter compressors.

Table of Comparison

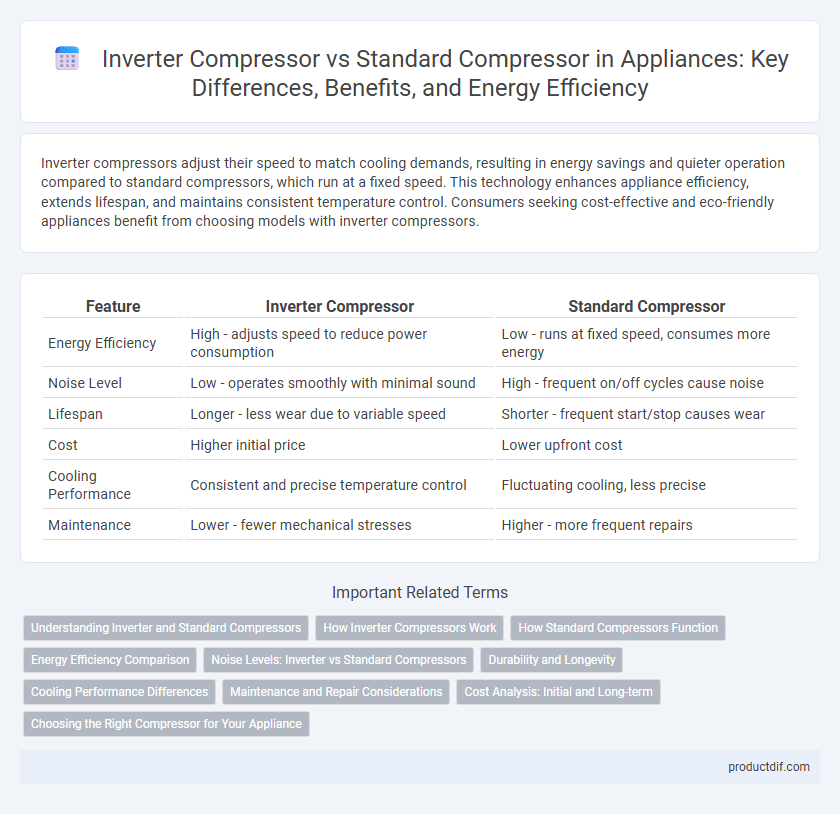

| Feature | Inverter Compressor | Standard Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to reduce power consumption | Low - runs at fixed speed, consumes more energy |

| Noise Level | Low - operates smoothly with minimal sound | High - frequent on/off cycles cause noise |

| Lifespan | Longer - less wear due to variable speed | Shorter - frequent start/stop causes wear |

| Cost | Higher initial price | Lower upfront cost |

| Cooling Performance | Consistent and precise temperature control | Fluctuating cooling, less precise |

| Maintenance | Lower - fewer mechanical stresses | Higher - more frequent repairs |

Understanding Inverter and Standard Compressors

Inverter compressors regulate motor speed to maintain consistent cooling, enhancing energy efficiency and reducing wear compared to standard compressors that operate at a fixed speed with frequent on-off cycles. The variable speed operation in inverter compressors results in quieter performance and longer lifespan due to less mechanical stress. Standard compressors, commonly found in traditional appliances, consume more power and may cause temperature fluctuations due to their continuous start-stop operation.

How Inverter Compressors Work

Inverter compressors operate by continuously adjusting their motor speed to match the cooling demand, resulting in precise temperature control and reduced energy consumption. Unlike standard compressors that switch on and off at full capacity, inverter compressors maintain consistent operation at varying speeds, enhancing efficiency and extending appliance lifespan. This technology lowers electricity bills while providing quieter performance in refrigerators, air conditioners, and other cooling appliances.

How Standard Compressors Function

Standard compressors operate using a fixed-speed motor that cycles on and off to regulate temperature, resulting in variable energy consumption and consistent output power during each cycle. These compressors maintain refrigeration by rapidly compressing refrigerant gas to increase its pressure and temperature, then allowing it to expand and cool within the appliance. Their simpler design and lower initial cost often lead to higher energy usage and less precise temperature control compared to inverter compressors.

Energy Efficiency Comparison

Inverter compressors optimize energy consumption by adjusting motor speed to match cooling demand, resulting in up to 30-50% energy savings compared to standard compressors that operate at fixed speeds. Standard compressors cycle on and off, causing frequent power surges and higher electricity usage. The adaptive technology in inverter compressors leads to reduced wear and improved overall efficiency in appliances such as refrigerators and air conditioners.

Noise Levels: Inverter vs Standard Compressors

Inverter compressors operate at variable speeds, significantly reducing noise levels compared to standard compressors that run at fixed speeds and generate louder, more constant noise during operation. The noise reduction in inverter compressors enhances user comfort, especially in quiet environments such as bedrooms or offices. Standard compressors produce higher decibel sounds due to frequent motor start-stop cycles, whereas inverter compressors maintain a consistent, low noise output by adjusting power use smoothly.

Durability and Longevity

Inverter compressors offer superior durability and longevity compared to standard compressors due to their ability to operate at variable speeds, reducing wear and tear. Standard compressors frequently cycle on and off, causing more mechanical stress and shorter lifespan. The advanced technology in inverter compressors ensures consistent performance and energy efficiency, extending appliance life significantly.

Cooling Performance Differences

Inverter compressors adjust their speed to match cooling demand, resulting in more consistent and efficient temperature control compared to standard compressors, which operate at fixed speeds and frequently cycle on and off. This variable-speed operation reduces energy consumption and maintains steadier cooling levels, enhancing overall appliance performance. Consequently, appliances with inverter compressors deliver faster cooling and greater temperature stability than those with standard compressors.

Maintenance and Repair Considerations

Inverter compressors require less frequent maintenance compared to standard compressors due to their variable-speed operation, which reduces wear and tear on components. Repair costs for inverter compressors can be higher because of advanced electronics and specialized parts, while standard compressors often have simpler, more affordable repairs. Regular maintenance of inverter compressors often involves software updates and diagnostics, whereas standard compressors typically need mechanical part checks and lubrication.

Cost Analysis: Initial and Long-term

Inverter compressors typically have a higher initial cost compared to standard compressors due to advanced technology and variable speed capabilities. Long-term savings arise from reduced energy consumption, with inverter models using up to 30-50% less electricity, resulting in lower utility bills over the appliance's lifespan. Maintenance costs for inverter compressors tend to be lower as they experience less wear and tear, whereas standard compressors may require more frequent repairs due to constant on/off cycles.

Choosing the Right Compressor for Your Appliance

Selecting the right compressor for your appliance depends on energy efficiency and performance requirements. Inverter compressors adjust their speed to match cooling demand, reducing energy consumption and noise levels, making them ideal for refrigerators and air conditioners. Standard compressors operate at a fixed speed, offering lower upfront costs but higher energy usage and wear, suitable for budget-conscious buyers or less frequently used appliances.

Inverter compressor vs Standard compressor Infographic

productdif.com

productdif.com