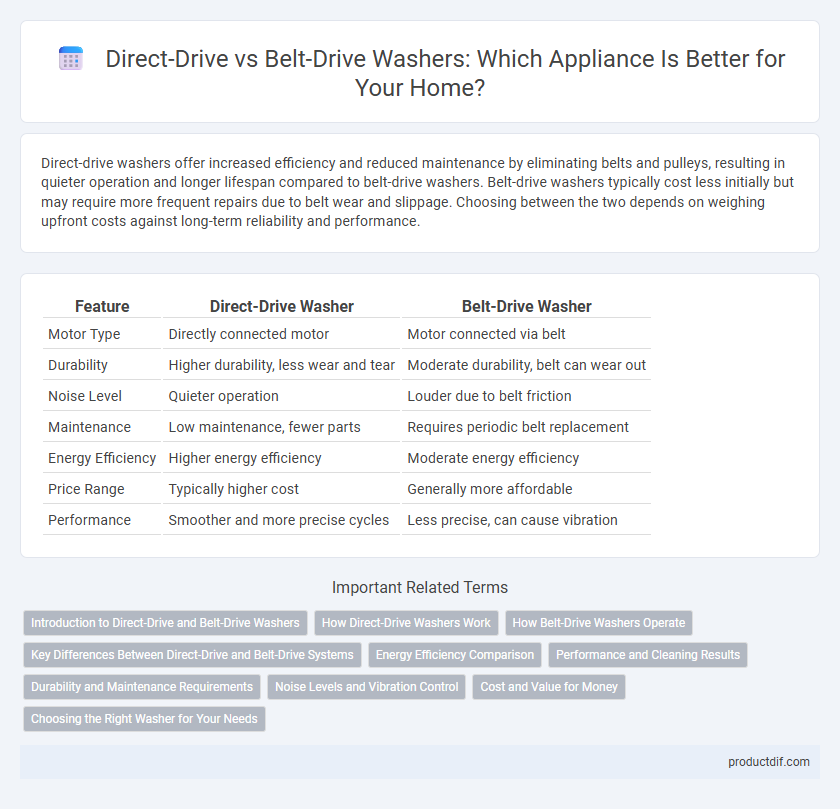

Direct-drive washers offer increased efficiency and reduced maintenance by eliminating belts and pulleys, resulting in quieter operation and longer lifespan compared to belt-drive washers. Belt-drive washers typically cost less initially but may require more frequent repairs due to belt wear and slippage. Choosing between the two depends on weighing upfront costs against long-term reliability and performance.

Table of Comparison

| Feature | Direct-Drive Washer | Belt-Drive Washer |

|---|---|---|

| Motor Type | Directly connected motor | Motor connected via belt |

| Durability | Higher durability, less wear and tear | Moderate durability, belt can wear out |

| Noise Level | Quieter operation | Louder due to belt friction |

| Maintenance | Low maintenance, fewer parts | Requires periodic belt replacement |

| Energy Efficiency | Higher energy efficiency | Moderate energy efficiency |

| Price Range | Typically higher cost | Generally more affordable |

| Performance | Smoother and more precise cycles | Less precise, can cause vibration |

Introduction to Direct-Drive and Belt-Drive Washers

Direct-drive washers feature a motor directly connected to the drum, reducing vibration and mechanical parts for increased durability and efficiency. Belt-drive washers use a belt and pulley system to rotate the drum, typically providing a quieter operation but with more components subject to wear. Understanding these fundamental differences helps consumers choose based on noise preference, maintenance needs, and overall machine longevity.

How Direct-Drive Washers Work

Direct-drive washers operate by connecting the motor directly to the wash drum, eliminating the need for belts or pulleys, which results in fewer moving parts and less mechanical friction. This design enhances energy efficiency and reduces noise levels during operation, making the washer more reliable and durable over time. The direct motor control also allows for precise drum movements, optimizing wash cycles and improving cleaning performance.

How Belt-Drive Washers Operate

Belt-drive washers operate using a motor connected to the drum via a rubber belt, which rotates the drum to wash clothes. This mechanism allows for smooth and consistent drum movement while absorbing vibrations during spins. The belt system requires occasional maintenance or replacement to ensure optimal washer performance and longevity.

Key Differences Between Direct-Drive and Belt-Drive Systems

Direct-drive washers feature a motor directly connected to the drum, eliminating belts and pulleys, resulting in quieter operation and reduced maintenance. Belt-drive washers rely on a belt connecting the motor to the drum, which can produce more noise and requires periodic belt replacement. The direct-drive system generally offers better energy efficiency and longer lifespan compared to belt-drive models.

Energy Efficiency Comparison

Direct-drive washers deliver superior energy efficiency by eliminating the belt and pulley system, which reduces mechanical friction and energy loss during operation. Belt-drive washers typically consume more electricity due to the additional components that require energy to function and maintain. Consumers seeking lower utility bills and eco-friendly options benefit more from direct-drive models, which often exceed ENERGY STAR standards for energy efficiency.

Performance and Cleaning Results

Direct-drive washers deliver superior performance by eliminating belts and pulleys, resulting in quieter operation and more efficient energy use. The direct motor control enhances drum rotation precision, providing better agitation and improved cleaning results for heavily soiled clothes. In contrast, belt-drive washers may experience more vibration and wear over time, potentially affecting cleaning consistency and appliance longevity.

Durability and Maintenance Requirements

Direct-drive washers feature a motor directly connected to the drum, reducing moving parts and resulting in enhanced durability and fewer maintenance needs compared to belt-drive washers. Belt-drive washers rely on a belt and pulley system prone to wear and require periodic belt replacement and tension adjustments. The direct-drive mechanism minimizes vibration and mechanical failure, making it a preferred choice for long-lasting performance and reduced upkeep.

Noise Levels and Vibration Control

Direct-drive washers eliminate belts and pulleys, resulting in significantly reduced noise levels and enhanced vibration control during high-speed spin cycles. Belt-drive washers often produce more noise due to the friction and wear between belts and pulleys, which can lead to increased vibration and mechanical noise over time. Advanced direct-drive technology integrates the motor with the drum, providing smoother operation and greater durability in noise-sensitive environments.

Cost and Value for Money

Direct-drive washers typically have a higher upfront cost due to their advanced technology and fewer moving parts, which can lead to lower maintenance expenses over time. Belt-drive washers are generally more affordable initially but may incur higher repair and replacement costs because of increased mechanical wear. When considering value for money, direct-drive washers offer greater long-term savings and reliability despite the steeper initial investment.

Choosing the Right Washer for Your Needs

Direct-drive washers offer greater energy efficiency and reduced noise due to their motor being directly attached to the drum, making them ideal for small spaces and frequent use. Belt-drive washers feature a belt connecting the motor to the drum, allowing easier and less expensive repairs but potentially higher noise levels and vibration. Selecting the right washer depends on your priorities for maintenance ease, noise tolerance, and energy consumption.

Direct-Drive Washer vs Belt-Drive Washer Infographic

productdif.com

productdif.com