Direct firing involves heating raw, unfired clay in a kiln to achieve its final strength and durability, resulting in an efficient but riskier process due to potential defects like warping or cracking. Biscuit firing, also known as bisque firing, first hardens the clay at a lower temperature, creating a porous but sturdy base that can be glazed and then fired again for enhanced finish and durability in tableware pet products. Choosing between these methods impacts the quality, appearance, and resilience of ceramic pet bowls and dishes.

Table of Comparison

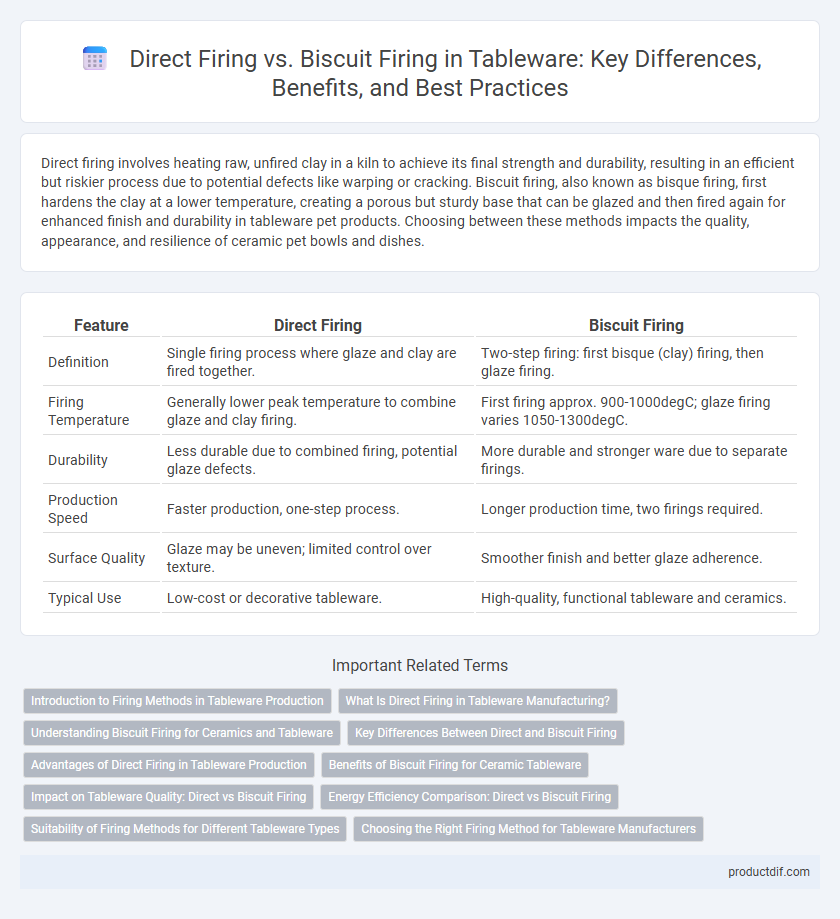

| Feature | Direct Firing | Biscuit Firing |

|---|---|---|

| Definition | Single firing process where glaze and clay are fired together. | Two-step firing: first bisque (clay) firing, then glaze firing. |

| Firing Temperature | Generally lower peak temperature to combine glaze and clay firing. | First firing approx. 900-1000degC; glaze firing varies 1050-1300degC. |

| Durability | Less durable due to combined firing, potential glaze defects. | More durable and stronger ware due to separate firings. |

| Production Speed | Faster production, one-step process. | Longer production time, two firings required. |

| Surface Quality | Glaze may be uneven; limited control over texture. | Smoother finish and better glaze adherence. |

| Typical Use | Low-cost or decorative tableware. | High-quality, functional tableware and ceramics. |

Introduction to Firing Methods in Tableware Production

Direct firing involves placing unfired clay pieces directly into the kiln, allowing the glaze and clay to mature simultaneously, resulting in vibrant surface finishes but requiring precise temperature control. Biscuit firing, or bisque firing, is an initial low-temperature firing that hardens the clay body before glazing, improving durability and glaze adherence while reducing the risk of defects during the glaze firing stage. Both firing methods impact the strength, texture, and aesthetic qualities of tableware, influencing production efficiency and final product quality.

What Is Direct Firing in Tableware Manufacturing?

Direct firing in tableware manufacturing refers to the process where ceramic pieces are fired for the first time without undergoing a preliminary biscuit firing stage. This method eliminates the bisque firing step, allowing the raw clay body to be heated directly to the maturation temperature, which can save time and energy while also affecting the final texture and strength of the tableware. Manufacturers often choose direct firing for certain porcelain or stoneware products due to its efficiency and the ability to produce denser, less porous ceramics.

Understanding Biscuit Firing for Ceramics and Tableware

Biscuit firing, also known as bisque firing, is a crucial first kiln firing process in ceramics that hardens the ware without vitrifying it, making it ideal for creating durable tableware. This firing typically occurs at temperatures between 900degC and 1000degC, driving out physical and chemical water to prepare the clay body for glazing and final firing. Understanding biscuit firing enhances the production of quality ceramic tableware by ensuring strength, porosity control, and optimal glaze adhesion before the direct firing or glaze firing stage.

Key Differences Between Direct and Biscuit Firing

Direct firing involves subjecting unglazed, raw ceramic pieces to high temperatures in a kiln, resulting in a single firing process that fuses the clay and glaze simultaneously. Biscuit firing, also known as bisque firing, consists of an initial firing of the clay body at a lower temperature to harden the ware, followed by a second glaze firing that melts and bonds the glaze to the ceramic surface. The key differences lie in process stages, temperature management, and the durability of the ware after each firing, with direct firing offering faster production but potential glaze imperfections, while biscuit firing yields stronger, more refined finishes due to controlled, separate firings.

Advantages of Direct Firing in Tableware Production

Direct firing in tableware production offers enhanced durability by creating a denser ceramic body through a single high-temperature firing process. This method significantly reduces production time and energy consumption compared to biscuit firing, leading to cost efficiency. The improved glaze adhesion and fewer defects result in higher-quality, visually appealing tableware with greater resistance to chipping and wear.

Benefits of Biscuit Firing for Ceramic Tableware

Biscuit firing enhances the durability and strength of ceramic tableware by removing moisture and solidifying the clay body before glazing, reducing warping and defects during the glaze firing stage. This process improves the final product's structural integrity and surface quality, resulting in more aesthetically consistent and functional tableware. Manufacturers benefit from fewer rejects and enhanced glazing adhesion, ensuring longer-lasting and higher-quality ceramic pieces.

Impact on Tableware Quality: Direct vs Biscuit Firing

Direct firing involves glazing and firing the tableware in a single process, resulting in a more vibrant and durable finish due to the continuous vitrification that enhances glaze adhesion. Biscuit firing, which first hardens the unglazed ceramic body before applying glaze in a second firing, allows for better control over glaze texture and thickness but may produce a slightly less integrated surface. The choice between direct and biscuit firing significantly affects the tableware's durability, resistance to chipping, and aesthetic appeal, with direct firing generally providing superior strength and a smoother finish.

Energy Efficiency Comparison: Direct vs Biscuit Firing

Direct firing eliminates the biscuit firing stage by applying glaze to unfired ware, reducing overall kiln cycles and energy consumption significantly compared to traditional biscuit firing, which requires two separate firings. Energy use in direct firing can be up to 30-40% lower due to the single firing approach, cutting down gas or electricity costs and emissions. Biscuit firing, while offering greater control over glaze quality, inherently consumes more energy because of its dual-firing process, making direct firing the more energy-efficient option for large-scale tableware production.

Suitability of Firing Methods for Different Tableware Types

Direct firing suits durable stoneware and porcelain items that require a uniform glaze finish and higher durability, making it ideal for everyday tableware. Biscuit firing is preferable for delicate earthenware or bone china, allowing detailed glazing or painting after the initial firing stage, enhancing decorative elements. Choosing the appropriate firing method depends on the clay body and desired surface qualities of the tableware, ensuring optimal strength and aesthetic appeal.

Choosing the Right Firing Method for Tableware Manufacturers

Direct firing offers tableware manufacturers a faster production process by firing glazed ceramics in a single kiln cycle, enhancing efficiency and reducing energy consumption. Biscuit firing involves an initial bisque firing to harden the clay body, followed by glazing and a second firing, which provides greater control over glaze quality and durability. Selecting the appropriate firing method depends on the desired finish, production volume, and cost considerations specific to tableware manufacturing.

Direct Firing vs Biscuit Firing Infographic

productdif.com

productdif.com