Wire-O binding offers a professional, sturdy finish with double loops that securely hold pages while allowing them to lie flat, ideal for presentations and notebooks. Spiral binding uses a single continuous coil that easily accommodates various page counts and provides flexibility for flipping pages 360 degrees. Choosing between Wire-O and spiral binding depends on the desired durability, aesthetic appeal, and ease of use for daily handling.

Table of Comparison

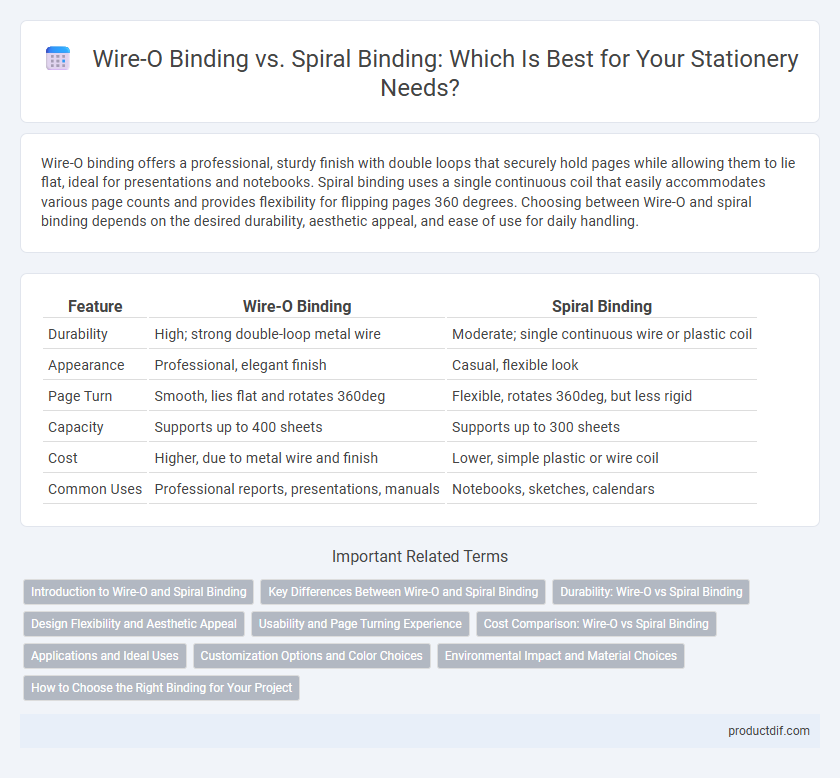

| Feature | Wire-O Binding | Spiral Binding |

|---|---|---|

| Durability | High; strong double-loop metal wire | Moderate; single continuous wire or plastic coil |

| Appearance | Professional, elegant finish | Casual, flexible look |

| Page Turn | Smooth, lies flat and rotates 360deg | Flexible, rotates 360deg, but less rigid |

| Capacity | Supports up to 400 sheets | Supports up to 300 sheets |

| Cost | Higher, due to metal wire and finish | Lower, simple plastic or wire coil |

| Common Uses | Professional reports, presentations, manuals | Notebooks, sketches, calendars |

Introduction to Wire-O and Spiral Binding

Wire-O binding uses double-looped metal wire to secure pages, offering a professional and durable finish ideal for presentations and reports. Spiral binding employs a continuous plastic or metal coil threaded through punched holes, providing flexibility and the ability to lay documents flat for easy handling. Both methods enhance document usability but differ in durability and aesthetic appeal, catering to various stationery and printing needs.

Key Differences Between Wire-O and Spiral Binding

Wire-O binding uses double loops of metal wire that create a sturdy, professional finish, while spiral binding employs a continuous plastic or metal coil allowing pages to rotate 360 degrees. Wire-O offers lay-flat capabilities and a polished appearance preferred for presentations, whereas spiral binding is more flexible and cost-effective, ideal for notebooks and manuals. The choice depends on the importance of durability, aesthetics, and budget in stationery projects.

Durability: Wire-O vs Spiral Binding

Wire-O binding offers superior durability compared to spiral binding due to its double-loop metal mechanism, which resists bending and deformation over time. Spiral binding, typically made from single continuous plastic or metal coils, is more prone to unwinding and damage with frequent handling. For projects requiring a robust and long-lasting finish, Wire-O binding provides enhanced structural integrity and longevity.

Design Flexibility and Aesthetic Appeal

Wire-O binding offers superior design flexibility and a sleek, professional aesthetic ideal for corporate documents, allowing books to lay flat and pages to turn smoothly. Spiral binding provides a more casual look with vibrant color options and greater customization for varied paper sizes but may lack the refined finish of Wire-O. Choosing between the two depends on whether the priority is a polished appearance or creative, budget-friendly designs.

Usability and Page Turning Experience

Wire-O binding offers superior durability and allows pages to lie flat, enhancing usability for frequent reference and note-taking. Spiral binding enables full 360-degree page rotation, providing flexibility for compact handling and easier flipping of pages. Both options improve page-turning experience but Wire-O binding delivers a more polished appearance while spiral binding excels in portability and versatility.

Cost Comparison: Wire-O vs Spiral Binding

Wire-O binding typically incurs higher costs than spiral binding due to its more complex manufacturing process and premium materials like double loops of metal wire. Spiral binding remains a budget-friendly choice, using single continuous plastic or metal coils that are easier to produce and assemble. Businesses aiming to balance durability and affordability often weigh these cost differences against project requirements and volume.

Applications and Ideal Uses

Wire-O binding offers a professional finish and is ideal for presenting reports, manuals, and calendars that require a sleek appearance and easy page turning, making it perfect for corporate and marketing materials. Spiral binding provides flexibility and durability, better suited for notebooks, workbooks, and cookbooks that undergo frequent handling and need to lie flat or fold back completely. Both bindings accommodate varied paper sizes and thicknesses, with Wire-O preferred for polished presentations and Spiral favored for practical, everyday use.

Customization Options and Color Choices

Wire-O binding offers superior customization options with versatile color selections and the ability to use double-loop wires for a professional finish. Spiral binding provides a wide range of colors, but customization is typically limited to single-loop coils, making it ideal for creative, colorful presentations. Both binding methods enhance visual appeal, with Wire-O preferred for durability and Spiral favored for flexibility and vibrancy.

Environmental Impact and Material Choices

Wire-O binding utilizes double-looped metal wires, often made from recyclable steel or aluminum, making it a more sustainable choice compared to plastic-based spiral bindings, which contribute to non-biodegradable waste. Spiral binding primarily employs PVC or PET plastics, materials with higher environmental footprints due to their production and disposal challenges. Choosing Wire-O binding supports eco-friendly stationery by promoting the use of recyclable metals and reducing plastic waste in document finishing options.

How to Choose the Right Binding for Your Project

Selecting the right binding for your project depends on factors such as durability, flexibility, and appearance. Wire-O binding offers a professional look with sturdy metal coils that allow pages to lie flat and turn 360 degrees, ideal for presentations and manuals. Spiral binding provides cost-effective, easy page turning with plastic or metal coils, suited for notebooks and everyday documents.

Wire-O Binding vs Spiral Binding Infographic

productdif.com

productdif.com