Plastic rulers offer lightweight convenience and are often more affordable, making them ideal for everyday school and office use. Metal rulers provide superior durability and precision, resisting warping and offering cleaner, more accurate measurements essential for technical drawing or professional tasks. Choosing between plastic and metal rulers depends on the balance between cost, durability, and the need for accuracy in specific applications.

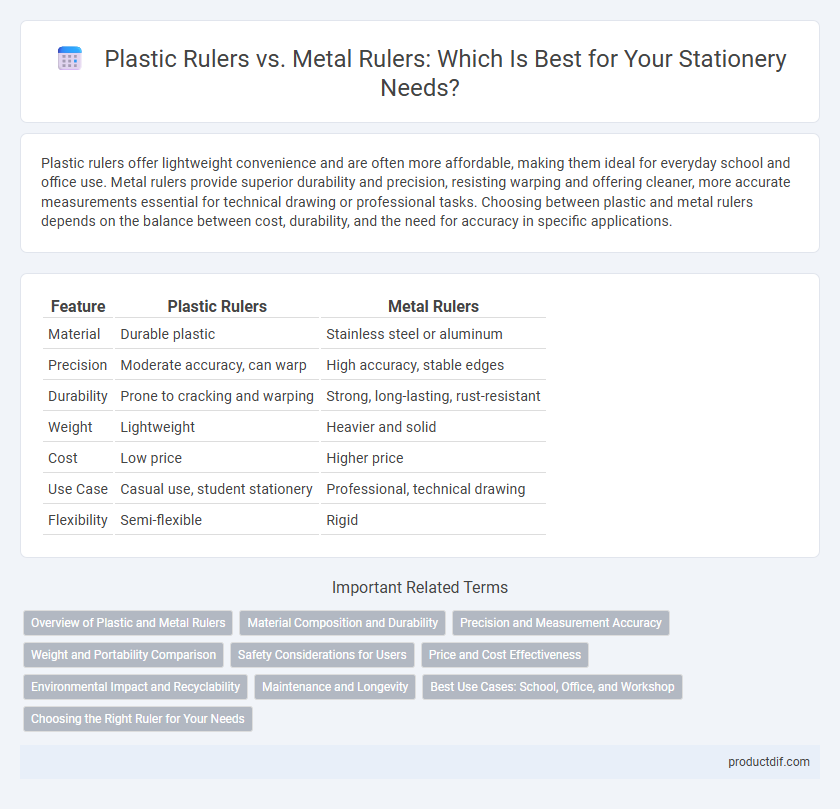

Table of Comparison

| Feature | Plastic Rulers | Metal Rulers |

|---|---|---|

| Material | Durable plastic | Stainless steel or aluminum |

| Precision | Moderate accuracy, can warp | High accuracy, stable edges |

| Durability | Prone to cracking and warping | Strong, long-lasting, rust-resistant |

| Weight | Lightweight | Heavier and solid |

| Cost | Low price | Higher price |

| Use Case | Casual use, student stationery | Professional, technical drawing |

| Flexibility | Semi-flexible | Rigid |

Overview of Plastic and Metal Rulers

Plastic rulers are lightweight, flexible, and often transparent, making them ideal for detailed measurements and drawing in schools or offices. Metal rulers, typically made from stainless steel or aluminum, provide durability, resistance to wear, and precise, straight edges suitable for technical and industrial use. Both materials offer unique advantages depending on the need for flexibility, durability, and accuracy in measurement tasks.

Material Composition and Durability

Plastic rulers are typically made from acrylic or polystyrene, offering lightweight flexibility but prone to bending and cracking under pressure. Metal rulers, commonly crafted from stainless steel or aluminum, provide superior durability and resistance to wear, ensuring long-lasting precision. The material composition directly impacts the ruler's performance, with metal rulers favored for heavy-duty use and plastic rulers suited for general, everyday tasks.

Precision and Measurement Accuracy

Plastic rulers offer flexibility and are lightweight but may warp over time, affecting measurement accuracy. Metal rulers provide superior precision due to their rigidity and resistance to wear, ensuring consistent measurements in professional and technical tasks. For tasks requiring exact measurements, metal rulers are preferred for their durability and reliable scale markings.

Weight and Portability Comparison

Plastic rulers are significantly lighter than metal rulers, making them more convenient for carrying in pencil cases or backpacks. Metal rulers, while heavier, offer increased durability but may add bulk to your stationery kit. Weight differences between plastic and metal rulers typically range from a few grams to over 50 grams, influencing portability for daily use.

Safety Considerations for Users

Plastic rulers often provide enhanced safety due to their lightweight, flexible composition, minimizing the risk of cuts or injuries during use. Metal rulers, while more durable and precise, may have sharper edges that require careful handling to prevent accidental harm. Choosing a ruler with rounded edges or a protective casing can significantly improve safety, especially in environments with children or frequent users.

Price and Cost Effectiveness

Plastic rulers are generally more affordable, making them a cost-effective choice for students and everyday use. Metal rulers, while pricier, offer enhanced durability and precision, reducing replacement frequency and long-term expenses. Choosing between plastic and metal rulers depends on balancing initial cost with durability and accuracy needs.

Environmental Impact and Recyclability

Plastic rulers contribute significantly to environmental pollution due to their non-biodegradable nature and limited recycling options, often ending up in landfills or oceans. Metal rulers, commonly made from aluminum or stainless steel, offer greater recyclability and durability, reducing the frequency of replacement and waste generation. Choosing metal rulers supports sustainable practices by minimizing plastic waste and promoting resource recovery through established metal recycling processes.

Maintenance and Longevity

Plastic rulers require minimal maintenance but are prone to scratches and warping over time, reducing their accuracy. Metal rulers, typically made of stainless steel or aluminum, resist wear and provide long-lasting precision with occasional cleaning to prevent rust or tarnish. When prioritizing durability and consistent measurement, metal rulers offer superior longevity compared to plastic alternatives.

Best Use Cases: School, Office, and Workshop

Plastic rulers are ideal for school use due to their lightweight design, flexibility, and affordability, making them perfect for students. Metal rulers offer greater durability and precision, suitable for office settings where detailed measurements are required. In workshops, metal rulers excel because of their resistance to wear and ability to maintain accuracy during heavy-duty tasks.

Choosing the Right Ruler for Your Needs

Plastic rulers offer lightweight flexibility and affordability, making them ideal for students and casual use, while metal rulers provide durability and precision suitable for professional drafting and heavy-duty tasks. Consider the specific requirements of your project--metal rulers resist warping and provide sharp edges for accurate measurements, whereas plastic rulers may break under pressure or lose straightness over time. Selecting the right ruler depends on balancing budget constraints with the need for longevity and measurement accuracy.

Plastic rulers vs Metal rulers Infographic

productdif.com

productdif.com