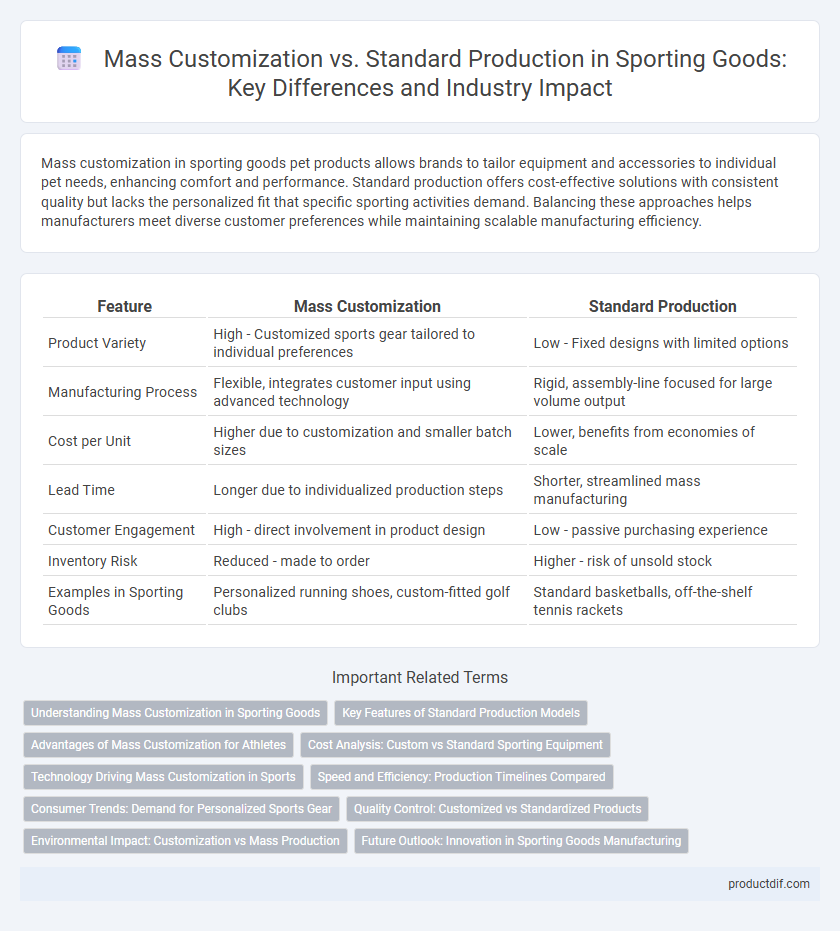

Mass customization in sporting goods pet products allows brands to tailor equipment and accessories to individual pet needs, enhancing comfort and performance. Standard production offers cost-effective solutions with consistent quality but lacks the personalized fit that specific sporting activities demand. Balancing these approaches helps manufacturers meet diverse customer preferences while maintaining scalable manufacturing efficiency.

Table of Comparison

| Feature | Mass Customization | Standard Production |

|---|---|---|

| Product Variety | High - Customized sports gear tailored to individual preferences | Low - Fixed designs with limited options |

| Manufacturing Process | Flexible, integrates customer input using advanced technology | Rigid, assembly-line focused for large volume output |

| Cost per Unit | Higher due to customization and smaller batch sizes | Lower, benefits from economies of scale |

| Lead Time | Longer due to individualized production steps | Shorter, streamlined mass manufacturing |

| Customer Engagement | High - direct involvement in product design | Low - passive purchasing experience |

| Inventory Risk | Reduced - made to order | Higher - risk of unsold stock |

| Examples in Sporting Goods | Personalized running shoes, custom-fitted golf clubs | Standard basketballs, off-the-shelf tennis rackets |

Understanding Mass Customization in Sporting Goods

Mass customization in sporting goods enables athletes to tailor equipment such as shoes, apparel, and protective gear to their specific physical attributes and performance needs, enhancing comfort and effectiveness. This approach leverages advanced technologies like 3D scanning, CAD design, and on-demand manufacturing to produce personalized products without the high costs traditionally associated with bespoke items. Compared to standard production, which emphasizes uniformity and economies of scale, mass customization offers a competitive edge by addressing individual preferences and improving athlete satisfaction.

Key Features of Standard Production Models

Standard production models in sporting goods emphasize uniformity, cost-efficiency, and high-volume output, ensuring consistent quality across all units. These models utilize streamlined manufacturing processes and economies of scale to minimize production costs and maintain competitive pricing. Key features include limited design variations, standardized materials, and predictable supply chain logistics that facilitate rapid market availability.

Advantages of Mass Customization for Athletes

Mass customization in sporting goods allows athletes to obtain equipment tailored to their specific body measurements, playing style, and performance goals, enhancing comfort and effectiveness. Personalized gear improves injury prevention by accommodating unique biomechanics, leading to better overall athletic performance. This approach also fosters greater athlete satisfaction and brand loyalty due to the precise fit and functionality of customized products.

Cost Analysis: Custom vs Standard Sporting Equipment

Mass customization in sporting goods typically incurs higher initial costs due to specialized manufacturing processes and individualized designs, but it allows for price premiums and reduced inventory expenses. Standard production benefits from economies of scale, driving down per-unit costs through streamlined, repetitive manufacturing and bulk material purchasing. An effective cost analysis must consider setup costs, production volume, and customer demand variability to determine the optimal balance between customization and standardization.

Technology Driving Mass Customization in Sports

Advanced digital technologies such as 3D printing, AI-driven design software, and IoT-enabled manufacturing systems are revolutionizing mass customization in sports equipment, enabling precise tailoring to individual athlete specifications. These innovations allow brands to efficiently produce personalized footwear, apparel, and gear at scale, enhancing performance and user satisfaction. The integration of real-time data analytics further refines product adjustments, setting a new standard beyond traditional mass-produced sporting goods.

Speed and Efficiency: Production Timelines Compared

Mass customization in sporting goods enables manufacturers to produce personalized products rapidly by integrating flexible manufacturing systems, significantly reducing lead times compared to standard production. Standard production benefits from streamlined processes and economies of scale, allowing for high efficiency in producing large quantities but often resulting in longer wait times for customized orders. Advances in digital fabrication and automation have further accelerated mass customization timelines, challenging the speed advantages traditionally held by standard production.

Consumer Trends: Demand for Personalized Sports Gear

Consumer trends in the sporting goods industry show a growing demand for personalized sports gear, driven by preferences for unique designs, tailored fit, and enhanced performance. Mass customization enables brands to offer individualized options such as customized colors, materials, and engraved logos, increasing customer satisfaction and brand loyalty. Standard production, while cost-efficient for mass markets, often lacks the flexibility to meet specific consumer desires, making personalized solutions a competitive advantage in today's market.

Quality Control: Customized vs Standardized Products

Mass customization in sporting goods allows for tailored quality control protocols focused on individual specifications, enhancing product performance and user satisfaction. Standard production relies on uniform quality control measures to maintain consistency across large volumes, ensuring dependable durability and compliance with industry standards. Customized products undergo rigorous, variable inspections to meet specific athlete needs, while standardized products benefit from streamlined testing processes optimized for mass efficiency.

Environmental Impact: Customization vs Mass Production

Mass customization in sporting goods reduces environmental impact by minimizing overproduction and waste, tailoring products to consumer demand with precise material usage. In contrast, standard production often leads to excess inventory and discarded unsold goods, increasing resource consumption and landfill contributions. By optimizing supply chains and manufacturing processes for customization, the sporting goods industry can significantly lower carbon footprints and promote sustainable consumption.

Future Outlook: Innovation in Sporting Goods Manufacturing

Advancements in 3D printing and AI-driven design tools are driving the future of sporting goods manufacturing toward mass customization, enabling personalized performance and fit for individual athletes. Standard production remains essential for cost-effective high-volume items, but integrating smart materials and IoT technology fosters innovation that caters to specific user needs. The convergence of data analytics and flexible manufacturing systems promises enhanced product lifecycle management and sustainability in the sporting goods sector.

Mass customization vs Standard production Infographic

productdif.com

productdif.com