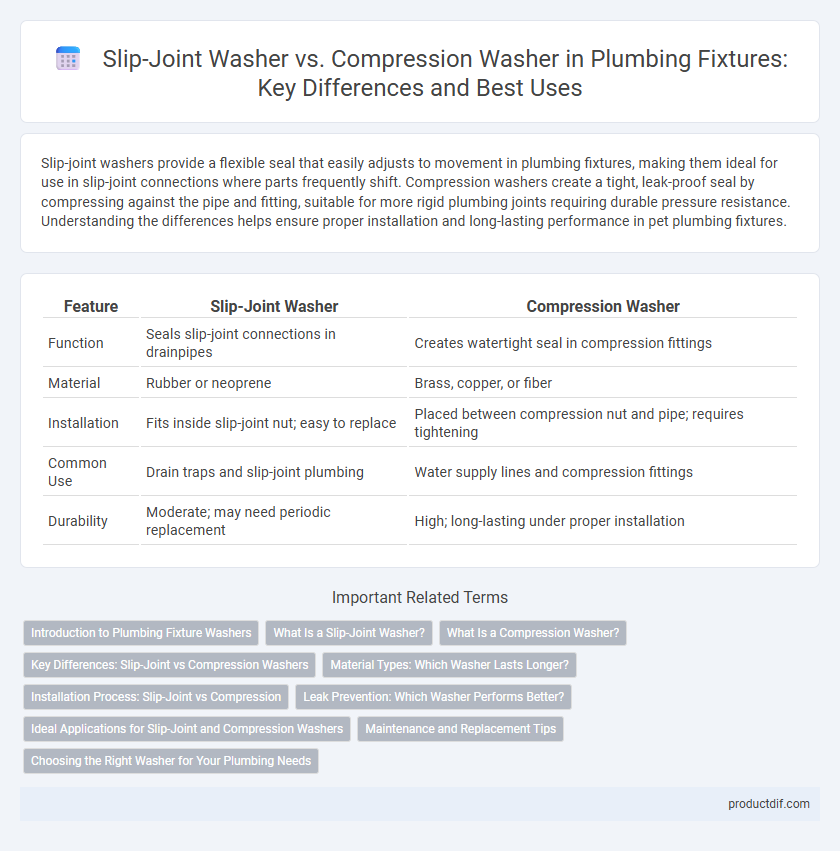

Slip-joint washers provide a flexible seal that easily adjusts to movement in plumbing fixtures, making them ideal for use in slip-joint connections where parts frequently shift. Compression washers create a tight, leak-proof seal by compressing against the pipe and fitting, suitable for more rigid plumbing joints requiring durable pressure resistance. Understanding the differences helps ensure proper installation and long-lasting performance in pet plumbing fixtures.

Table of Comparison

| Feature | Slip-Joint Washer | Compression Washer |

|---|---|---|

| Function | Seals slip-joint connections in drainpipes | Creates watertight seal in compression fittings |

| Material | Rubber or neoprene | Brass, copper, or fiber |

| Installation | Fits inside slip-joint nut; easy to replace | Placed between compression nut and pipe; requires tightening |

| Common Use | Drain traps and slip-joint plumbing | Water supply lines and compression fittings |

| Durability | Moderate; may need periodic replacement | High; long-lasting under proper installation |

Introduction to Plumbing Fixture Washers

Slip-joint washers are designed with a flexible rubber or plastic material that allows for easy sealing and adjustment in plumbing fixtures, particularly in slip-joint connections such as drainpipes. Compression washers, often made of metal or reinforced rubber, create a tight, leak-proof seal under pressure when compressed between two fittings, commonly used in supply line connections. Understanding the specific function and material composition of each washer type is essential for ensuring durable and watertight plumbing fixture installations.

What Is a Slip-Joint Washer?

A slip-joint washer is a flexible, flat sealing component used in plumbing slip-joint connections to create a watertight seal between pipes or fittings. Unlike rigid compression washers, slip-joint washers are designed to flex and compress within the joint, accommodating minor misalignments and preventing leaks in drain or trap assemblies. These washers are typically made of rubber or plastic, providing durability and ease of installation in sink drains and other slip-joint plumbing fixtures.

What Is a Compression Washer?

A compression washer is a sealing component used in plumbing fixtures to create a watertight connection by compressing between the fitting and the pipe. Unlike slip-joint washers, compression washers are typically made from durable materials such as rubber or plastic, designed to withstand high pressure and prevent leaks in compression fittings. These washers play a critical role in securing joints where pipes meet fixtures, ensuring reliable performance in water supply systems.

Key Differences: Slip-Joint vs Compression Washers

Slip-joint washers are designed to create a flexible seal that accommodates slight movements or misalignments in plumbing connections, often used in slip-joint plumbing fittings. Compression washers, made typically of rubber or plastic, provide a firm, watertight seal by compressing between the fitting and the pipe, ensuring leak-proof joints in compression fittings. Key differences include slip-joint washers' flexibility allowing ease of installation and adjustments, while compression washers deliver a tighter, more rigid seal ideal for permanent connections.

Material Types: Which Washer Lasts Longer?

Slip-joint washers are typically made from softer materials like rubber or neoprene, providing flexibility but less durability under constant pressure. Compression washers consist of harder materials such as brass or copper, offering superior resistance to wear and longer lifespan in plumbing fixtures. Brass compression washers are known to last significantly longer than rubber slip-joint washers due to their enhanced corrosion resistance and structural strength.

Installation Process: Slip-Joint vs Compression

Slip-joint washers are designed for easy installation and removal, commonly used in drain assemblies where the washer fits between two slip joint nuts, forming a watertight seal without requiring tightening tools. Compression washers require careful alignment and tightening with a wrench to compress the washer against the pipe or fitting, creating a strong, leak-resistant seal ideal for permanent or high-pressure connections. Proper installation of slip-joint washers involves hand-tightening to maintain flexibility, while compression washers demand precise torque application to prevent damage and ensure a secure fit.

Leak Prevention: Which Washer Performs Better?

Slip-joint washers, typically made of rubber or neoprene, provide flexible sealing that adapts to slight misalignments in plumbing fixtures, reducing the risk of leaks in slip-joint connections. Compression washers, often composed of harder materials like fiber or metal, create a tight, rigid seal by compressing between metal surfaces, making them highly effective for preventing leaks in compression fittings. For optimal leak prevention, compression washers generally perform better due to their ability to maintain a consistent, high-pressure seal under varying conditions.

Ideal Applications for Slip-Joint and Compression Washers

Slip-joint washers are ideal for movable connections in plumbing fixtures, such as sink drain pipes and trap assemblies, where frequent disassembly is required for cleaning or adjustments. Compression washers perform best in static, high-pressure applications like water supply lines and faucet connections, providing a watertight seal by compressing between fittings. Selecting slip-joint washers enhances flexibility in maintenance, while compression washers ensure durability and leak resistance in permanent fixture installations.

Maintenance and Replacement Tips

Slip-joint washers require regular inspection for cracks or flattening, as their rubber material can degrade over time, leading to leaks in plumbing fixtures. Compression washers, typically made from metal or reinforced materials, offer longer durability but need careful tightening to avoid deformation during replacement. Proper lubrication and avoiding overtightening ensure effective sealing and extend the lifespan of both slip-joint and compression washers in maintaining optimal plumbing performance.

Choosing the Right Washer for Your Plumbing Needs

Selecting the appropriate washer for plumbing fixtures depends on the specific application requirements and connection type. Slip-joint washers provide flexibility and easy adjustments for drain pipes, accommodating slight misalignments without leaks, while compression washers create a tighter seal ideal for high-pressure water connections and threaded fittings. Understanding the differences in material compatibility, sealing capability, and durability ensures a reliable, leak-free plumbing system.

slip-joint washer vs compression washer Infographic

productdif.com

productdif.com