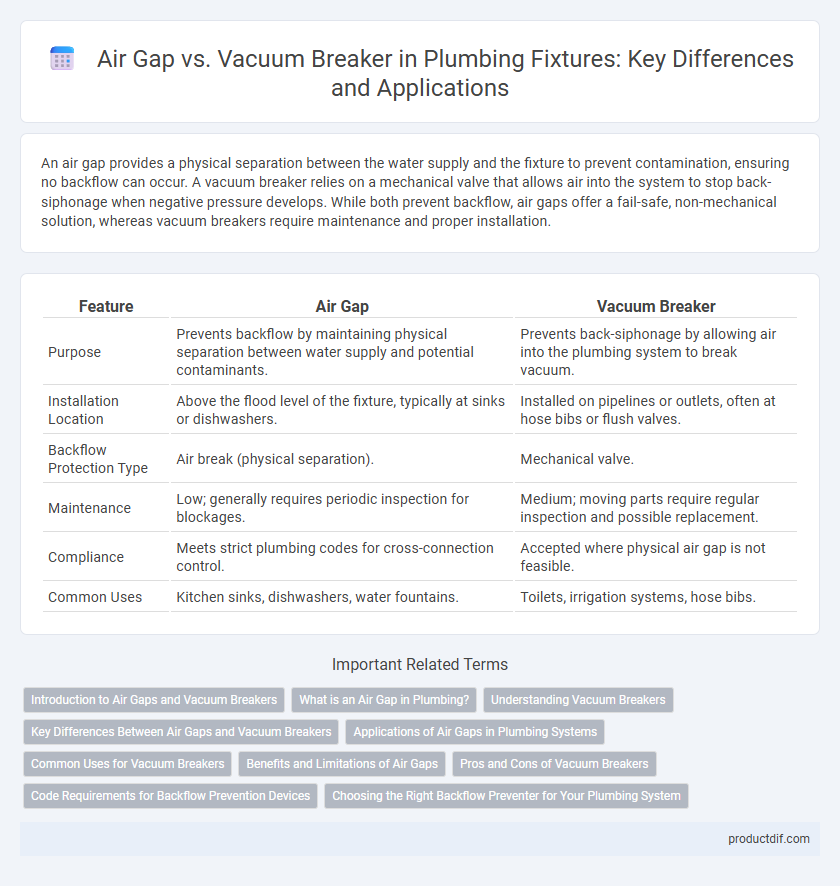

An air gap provides a physical separation between the water supply and the fixture to prevent contamination, ensuring no backflow can occur. A vacuum breaker relies on a mechanical valve that allows air into the system to stop back-siphonage when negative pressure develops. While both prevent backflow, air gaps offer a fail-safe, non-mechanical solution, whereas vacuum breakers require maintenance and proper installation.

Table of Comparison

| Feature | Air Gap | Vacuum Breaker |

|---|---|---|

| Purpose | Prevents backflow by maintaining physical separation between water supply and potential contaminants. | Prevents back-siphonage by allowing air into the plumbing system to break vacuum. |

| Installation Location | Above the flood level of the fixture, typically at sinks or dishwashers. | Installed on pipelines or outlets, often at hose bibs or flush valves. |

| Backflow Protection Type | Air break (physical separation). | Mechanical valve. |

| Maintenance | Low; generally requires periodic inspection for blockages. | Medium; moving parts require regular inspection and possible replacement. |

| Compliance | Meets strict plumbing codes for cross-connection control. | Accepted where physical air gap is not feasible. |

| Common Uses | Kitchen sinks, dishwashers, water fountains. | Toilets, irrigation systems, hose bibs. |

Introduction to Air Gaps and Vacuum Breakers

Air gaps and vacuum breakers are essential plumbing fixtures that prevent backflow and protect water quality by ensuring contamination does not enter the potable water supply. An air gap creates a physical separation between the water outlet and the flood level, while a vacuum breaker uses a mechanical valve to allow air into the system, preventing siphoning of contaminated water. Both devices comply with plumbing codes and health regulations, promoting safe water distribution in residential and commercial applications.

What is an Air Gap in Plumbing?

An air gap in plumbing is a physical separation between the water supply outlet and the flood-level rim of a fixture, preventing contaminated water from siphoning back into the clean water supply. This gap maintains potable water safety by creating a visible and measurable space, typically twice the diameter of the supply pipe. Unlike vacuum breakers, air gaps do not rely on mechanical parts, offering a fail-safe method to avoid cross-contamination in plumbing systems.

Understanding Vacuum Breakers

Vacuum breakers prevent backflow by allowing air to enter a plumbing system when negative pressure is detected, safeguarding potable water from contamination. Unlike air gaps that provide a physical separation between water supply and potential contaminants, vacuum breakers rely on mechanical components to maintain system integrity. Commonly installed in irrigation systems and hose bibs, vacuum breakers are essential for compliance with plumbing codes and ensuring water safety.

Key Differences Between Air Gaps and Vacuum Breakers

An air gap is a physical separation between a water outlet and the flood level of a fixture, preventing backflow by ensuring water cannot siphon back into the supply line, and is commonly used in sinks and dishwashers. A vacuum breaker, in contrast, is a mechanical device installed in piping systems to stop back-siphoning by allowing air to enter the system when negative pressure occurs, typically found in outdoor hose bibs and irrigation systems. While air gaps require no maintenance and provide absolute protection, vacuum breakers rely on moving parts and must be regularly inspected to ensure proper operation.

Applications of Air Gaps in Plumbing Systems

Air gaps are primarily used in plumbing systems to prevent backflow contamination by creating a physical separation between the water supply and potential sources of pollution, such as sinks, dishwashers, and irrigation systems. Common applications include kitchen faucets, laundry tubs, and outdoor hose bibs where air gaps ensure wastewater cannot siphon back into potable water lines. Unlike vacuum breakers, air gaps require no mechanical parts, making them reliable and maintenance-free solutions for maintaining water safety in residential and commercial plumbing.

Common Uses for Vacuum Breakers

Vacuum breakers are commonly used in irrigation systems, plumbing fixtures, and outdoor faucets to prevent backflow and protect potable water supplies from contamination. They are essential in applications where a temporary negative pressure might draw contaminated water back into the clean water supply. Unlike air gaps, vacuum breakers can be installed directly on pipes or fixtures for space-efficient backflow prevention.

Benefits and Limitations of Air Gaps

Air gaps provide a reliable backflow prevention method by physically separating water supply outlets from potential contaminants, ensuring clean water and compliance with plumbing codes. They are low-maintenance and do not rely on mechanical parts, reducing the risk of failure or breakdown over time. However, air gaps require sufficient vertical space and can cause water splashing, which may limit their use in compact installations or aesthetically sensitive areas.

Pros and Cons of Vacuum Breakers

Vacuum breakers prevent backflow by allowing air to enter the plumbing system, effectively protecting water supply lines from contamination. They are cost-effective and simple to install but may not provide as reliable protection in high-risk cross-connection scenarios compared to air gaps. However, vacuum breakers are vulnerable to freezing and require regular maintenance to ensure optimal performance.

Code Requirements for Backflow Prevention Devices

Air gaps and vacuum breakers are critical backflow prevention devices mandated by plumbing codes to protect potable water supplies from contamination. Plumbing codes such as the International Plumbing Code (IPC) and Uniform Plumbing Code (UPC) specify air gaps as mandatory for fixtures where the potable water supply discharges into a drain or receiving vessel, ensuring a physical separation to prevent backflow. Vacuum breakers are required in situations where air gaps are impractical, providing mechanical protection by preventing siphonage and are often specified for hose bibbs, irrigation systems, and equipment connections, with strict installation guidelines outlined to meet code compliance.

Choosing the Right Backflow Preventer for Your Plumbing System

Selecting the appropriate backflow preventer, such as an air gap or a vacuum breaker, depends on the specific plumbing system requirements and local codes. Air gaps provide a physical separation between potable water and potential contaminants, ensuring the highest level of protection without mechanical parts. Vacuum breakers are mechanical devices that prevent back-siphonage in pressurized systems but require regular maintenance to maintain effectiveness.

Air gap vs Vacuum breaker Infographic

productdif.com

productdif.com