Point-to-point wiring in musical instrument pedals offers enhanced signal clarity and easier customization, allowing precise control over component placement and reducing signal interference. PCB wiring streamlines production with consistent layouts, improving manufacturing efficiency and reliability, but can limit modification flexibility due to fixed circuit paths. Understanding the trade-offs helps musicians and technicians choose the best option for durability, repairability, and tonal quality in their pedals.

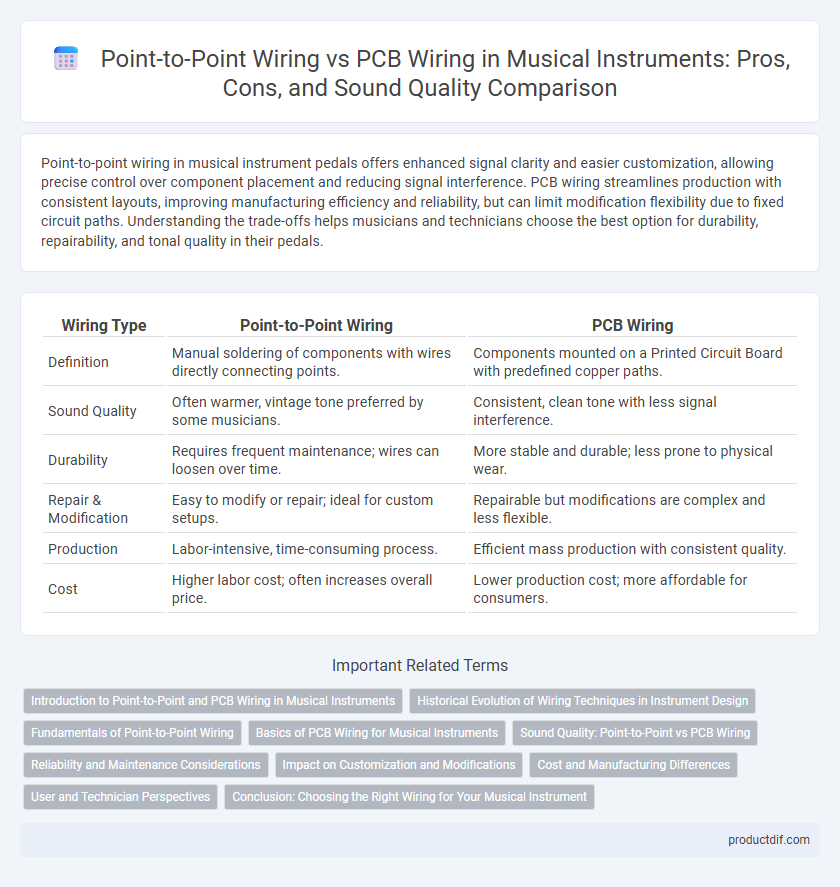

Table of Comparison

| Wiring Type | Point-to-Point Wiring | PCB Wiring |

|---|---|---|

| Definition | Manual soldering of components with wires directly connecting points. | Components mounted on a Printed Circuit Board with predefined copper paths. |

| Sound Quality | Often warmer, vintage tone preferred by some musicians. | Consistent, clean tone with less signal interference. |

| Durability | Requires frequent maintenance; wires can loosen over time. | More stable and durable; less prone to physical wear. |

| Repair & Modification | Easy to modify or repair; ideal for custom setups. | Repairable but modifications are complex and less flexible. |

| Production | Labor-intensive, time-consuming process. | Efficient mass production with consistent quality. |

| Cost | Higher labor cost; often increases overall price. | Lower production cost; more affordable for consumers. |

Introduction to Point-to-Point and PCB Wiring in Musical Instruments

Point-to-point wiring in musical instruments involves manually connecting components with individual wires, offering easy component replacement and a vintage tonal character favored in classic guitar amplifiers and effects pedals. Printed circuit board (PCB) wiring uses a fabricated board to mechanically support and electrically connect components, providing consistent performance, compact design, and efficient mass production in modern electronic instruments. Each method influences maintenance, durability, and tonal qualities, with point-to-point wiring often preferred for its warmth and customizability, while PCBs ensure reliability and scalability.

Historical Evolution of Wiring Techniques in Instrument Design

Point-to-point wiring, prevalent in early electric guitar and amplifier designs, involved manually soldering individual components together, offering easy repair and customization but limiting mass production. The shift to printed circuit board (PCB) wiring in the mid-20th century enabled more consistent, compact, and cost-effective manufacturing while supporting complex circuitry in modern instruments. This evolution reflects a balance between craftsmanship and efficiency, influencing reliability and tonal characteristics in musical instrument design.

Fundamentals of Point-to-Point Wiring

Point-to-point wiring in musical instruments involves manually connecting individual electronic components with wires, offering greater flexibility and ease of repair compared to printed circuit boards (PCBs). This method allows for precise customization and often results in a warmer, more authentic analog sound favored by audiophiles and vintage instrument enthusiasts. Its fundamental advantage lies in reducing signal interference and maintaining high-quality audio fidelity, crucial for guitars, amplifiers, and synthesizers.

Basics of PCB Wiring for Musical Instruments

PCB wiring for musical instruments involves mounting and soldering electronic components directly onto a printed circuit board, enabling compact and efficient layouts that improve signal integrity and reduce noise. This method contrasts with point-to-point wiring, which connects components with individual wires, often resulting in bulkier assemblies and increased susceptibility to interference. Understanding the basics of PCB design, such as trace routing, grounding techniques, and component placement, is crucial to optimizing performance and reliability in musical instrument circuitry.

Sound Quality: Point-to-Point vs PCB Wiring

Point-to-point wiring in musical instruments often results in richer, more dynamic sound quality due to reduced signal interference and shorter, more direct electrical paths. PCB wiring provides consistent performance and is easier to manufacture but may introduce subtle noise or tonal coloration because of standardized board layouts and added trace lengths. Musicians seeking vintage warmth typically prefer point-to-point wiring, while those prioritizing reliability and consistency lean toward PCB designs.

Reliability and Maintenance Considerations

Point-to-point wiring offers superior reliability in musical instruments due to its robust mechanical connections that withstand vibrations and stress better than PCB wiring. Maintenance is more straightforward with point-to-point wiring, as individual components and connections are accessible and easier to diagnose and repair. PCB wiring, while compact, often poses challenges in repairability and can suffer from trace damage, making point-to-point wiring the preferred choice for vintage-style or high-end instruments demanding durability.

Impact on Customization and Modifications

Point-to-point wiring in musical instruments offers greater flexibility for customization and modifications, allowing musicians and technicians to easily access and replace components without specialized equipment. PCB wiring provides a more compact and consistent layout, but is less adaptable for modifications due to the fixed circuit design. The choice between point-to-point and PCB wiring directly influences the ease of upgrading tone circuits, switching mechanisms, and wiring configurations in guitars, amplifiers, and effects pedals.

Cost and Manufacturing Differences

Point-to-point wiring involves manually soldering each connection, resulting in higher labor costs and longer assembly times, which makes it less cost-effective for mass production. PCB wiring uses automated processes to embed electrical pathways on a board, enabling faster manufacturing and consistent quality at a lower cost per unit. The difference in scalability and labor intensity makes PCB wiring the preferred choice for large-scale production of musical instruments like electric guitars and amplifiers.

User and Technician Perspectives

Point-to-point wiring in musical instruments offers easier repair and customization due to its straightforward layout, favored by technicians for quick troubleshooting and component replacement. PCB wiring provides consistent manufacturing quality and compact design, enhancing the user experience with reliable performance and reduced noise interference. Technicians may find PCBs more challenging to diagnose but benefit from standardized components and clearer schematic diagrams for complex instruments.

Conclusion: Choosing the Right Wiring for Your Musical Instrument

Point-to-point wiring offers superior signal clarity and ease of repair, making it ideal for vintage and boutique musical instruments seeking authentic tonal quality. PCB wiring provides consistent, compact, and cost-effective assembly crucial for mass-produced models requiring reliability and uniform performance. Assessing your instrument's intended use, maintenance preferences, and tonal goals ensures selecting the optimal wiring method for enhanced sound and durability.

Point-to-point wiring vs PCB wiring Infographic

productdif.com

productdif.com