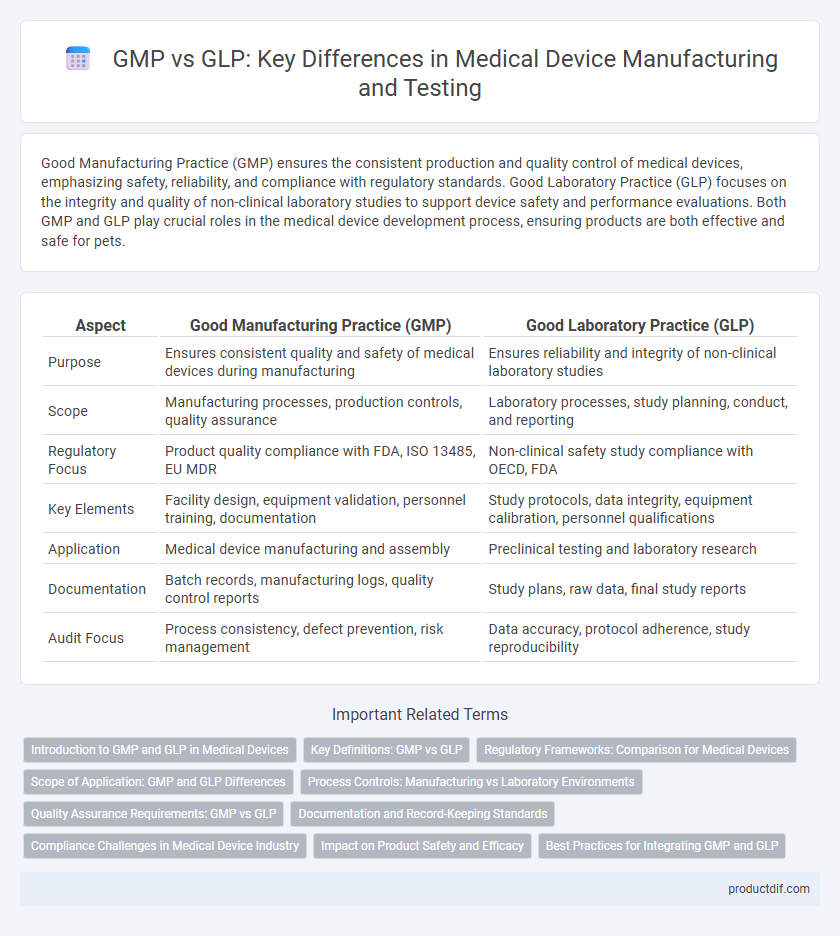

Good Manufacturing Practice (GMP) ensures the consistent production and quality control of medical devices, emphasizing safety, reliability, and compliance with regulatory standards. Good Laboratory Practice (GLP) focuses on the integrity and quality of non-clinical laboratory studies to support device safety and performance evaluations. Both GMP and GLP play crucial roles in the medical device development process, ensuring products are both effective and safe for pets.

Table of Comparison

| Aspect | Good Manufacturing Practice (GMP) | Good Laboratory Practice (GLP) |

|---|---|---|

| Purpose | Ensures consistent quality and safety of medical devices during manufacturing | Ensures reliability and integrity of non-clinical laboratory studies |

| Scope | Manufacturing processes, production controls, quality assurance | Laboratory processes, study planning, conduct, and reporting |

| Regulatory Focus | Product quality compliance with FDA, ISO 13485, EU MDR | Non-clinical safety study compliance with OECD, FDA |

| Key Elements | Facility design, equipment validation, personnel training, documentation | Study protocols, data integrity, equipment calibration, personnel qualifications |

| Application | Medical device manufacturing and assembly | Preclinical testing and laboratory research |

| Documentation | Batch records, manufacturing logs, quality control reports | Study plans, raw data, final study reports |

| Audit Focus | Process consistency, defect prevention, risk management | Data accuracy, protocol adherence, study reproducibility |

Introduction to GMP and GLP in Medical Devices

Good Manufacturing Practice (GMP) in medical devices ensures the consistent production and quality control of products, focusing on manufacturing processes, equipment, and personnel training to meet regulatory standards. Good Laboratory Practice (GLP) governs the non-clinical laboratory studies related to safety testing of medical devices, emphasizing data integrity, study protocols, and documentation. Both GMP and GLP are essential regulatory frameworks that improve device reliability, patient safety, and compliance with health authorities worldwide.

Key Definitions: GMP vs GLP

Good Manufacturing Practice (GMP) ensures that medical devices are consistently produced and controlled according to quality standards to minimize risks in production. Good Laboratory Practice (GLP) refers to a set of principles intended to assure the quality and integrity of non-clinical laboratory studies, including safety testing of medical devices. While GMP focuses on manufacturing processes and product quality, GLP emphasizes the validity and reliability of preclinical research data.

Regulatory Frameworks: Comparison for Medical Devices

Good Manufacturing Practice (GMP) for medical devices governs production and quality control to ensure product safety and compliance with regulatory standards such as FDA 21 CFR Part 820 and ISO 13485. Good Laboratory Practice (GLP) focuses on preclinical laboratory studies, ensuring the integrity and reliability of safety data in compliance with standards like OECD GLP principles. Both frameworks complement each other, with GMP emphasizing manufacturing processes and GLP concentrating on non-clinical laboratory testing within the regulatory framework for medical device approval.

Scope of Application: GMP and GLP Differences

Good Manufacturing Practice (GMP) governs the production and quality control processes of medical devices to ensure they meet safety and efficacy standards during manufacturing. Good Laboratory Practice (GLP), in contrast, applies to non-clinical laboratory studies that assess the safety and performance of medical devices before clinical use. The key distinction lies in GMP focusing on controlled manufacturing environments, while GLP emphasizes the integrity and reliability of preclinical research data.

Process Controls: Manufacturing vs Laboratory Environments

Good Manufacturing Practice (GMP) enforces strict process controls in manufacturing environments to ensure consistent product quality, focusing on production workflows, equipment validation, and contamination prevention. Good Laboratory Practice (GLP) emphasizes process controls in laboratory settings, prioritizing accurate data collection, equipment calibration, and traceability of test procedures. Both frameworks maintain rigorous documentation and quality assurance but target distinct phases in medical device development and production to uphold safety and efficacy standards.

Quality Assurance Requirements: GMP vs GLP

Good Manufacturing Practice (GMP) ensures quality assurance by regulating the manufacturing processes of medical devices to guarantee product safety, consistency, and compliance with regulatory standards. Good Laboratory Practice (GLP) focuses on the quality assurance of laboratory studies, emphasizing proper data collection, documentation, and validation to ensure reliable and reproducible preclinical research results. Both GMP and GLP are critical for regulatory compliance but differ in scope; GMP targets production and control, while GLP governs non-clinical laboratory testing quality.

Documentation and Record-Keeping Standards

Good Manufacturing Practice (GMP) mandates meticulous documentation and record-keeping to ensure product quality, traceability, and regulatory compliance throughout the medical device production process. Good Laboratory Practice (GLP) emphasizes accurate, consistent documentation of non-clinical laboratory studies to guarantee data integrity and reproducibility. Both frameworks require systematic record management but focus on different stages: GMP targets manufacturing controls, while GLP centers on laboratory testing protocols.

Compliance Challenges in Medical Device Industry

Compliance challenges in the medical device industry arise from the need to adhere to both Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP) standards, each governing different aspects of product development and quality control. GMP focuses on ensuring the safety, quality, and consistency of medical devices during manufacturing, while GLP pertains to the reliability and integrity of laboratory studies and testing procedures. Balancing strict regulatory requirements, documentation, and audit readiness for both GMP and GLP presents significant challenges for manufacturers striving to maintain compliance and market access.

Impact on Product Safety and Efficacy

Good Manufacturing Practice (GMP) ensures consistent production and quality control of medical devices, directly impacting product safety by minimizing defects and contamination. Good Laboratory Practice (GLP) governs non-clinical laboratory studies, providing reliable safety and efficacy data through standardized testing protocols. The integration of GMP and GLP standards enhances overall medical device safety and effectiveness by combining rigorous production oversight with validated preclinical research.

Best Practices for Integrating GMP and GLP

Integrating Good Manufacturing Practice (GMP) and Good Laboratory Practice (GLP) ensures seamless quality control from research to production in medical device development. Implementing standardized documentation, cross-functional training, and unified audit processes enhances compliance and data integrity across both manufacturing and laboratory environments. Collaborative workflows facilitate early detection of deviations, promoting consistent product safety and efficacy throughout the development lifecycle.

Good Manufacturing Practice (GMP) vs Good Laboratory Practice (GLP) Infographic

productdif.com

productdif.com