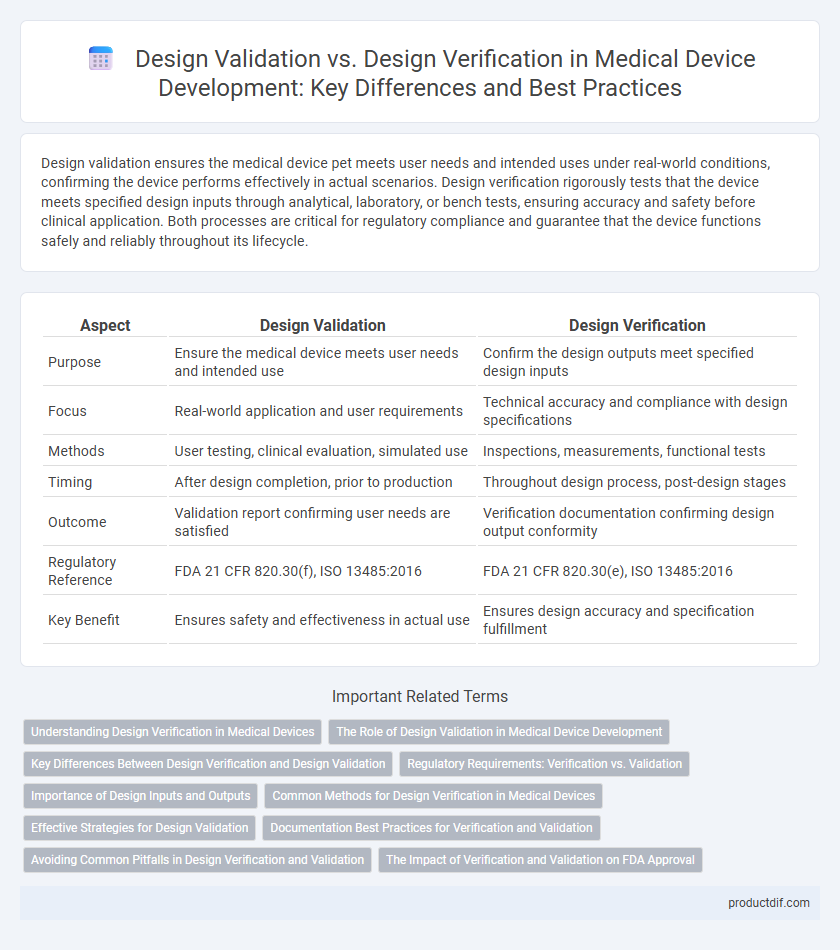

Design validation ensures the medical device pet meets user needs and intended uses under real-world conditions, confirming the device performs effectively in actual scenarios. Design verification rigorously tests that the device meets specified design inputs through analytical, laboratory, or bench tests, ensuring accuracy and safety before clinical application. Both processes are critical for regulatory compliance and guarantee that the device functions safely and reliably throughout its lifecycle.

Table of Comparison

| Aspect | Design Validation | Design Verification |

|---|---|---|

| Purpose | Ensure the medical device meets user needs and intended use | Confirm the design outputs meet specified design inputs |

| Focus | Real-world application and user requirements | Technical accuracy and compliance with design specifications |

| Methods | User testing, clinical evaluation, simulated use | Inspections, measurements, functional tests |

| Timing | After design completion, prior to production | Throughout design process, post-design stages |

| Outcome | Validation report confirming user needs are satisfied | Verification documentation confirming design output conformity |

| Regulatory Reference | FDA 21 CFR 820.30(f), ISO 13485:2016 | FDA 21 CFR 820.30(e), ISO 13485:2016 |

| Key Benefit | Ensures safety and effectiveness in actual use | Ensures design accuracy and specification fulfillment |

Understanding Design Verification in Medical Devices

Design verification in medical devices involves confirming that the product meets specified design inputs through tests, inspections, and analyses, ensuring accuracy, safety, and functionality. This process validates that each design output aligns with regulatory standards and user requirements before moving to production or clinical use. Proper design verification reduces the risk of device failures and supports FDA compliance under 21 CFR Part 820 quality system regulations.

The Role of Design Validation in Medical Device Development

Design validation in medical device development ensures that the final product meets user needs and intended uses under real-world conditions, confirming clinical safety and efficacy. It involves comprehensive testing and feedback from end-users, regulatory compliance checks, and risk management assessments aligned with ISO 13485 and FDA guidelines. This process reduces post-market failures and supports successful regulatory approvals by demonstrating that the device performs as intended in actual clinical environments.

Key Differences Between Design Verification and Design Validation

Design verification confirms that a medical device meets specified design inputs through objective evidence, ensuring accuracy in components and functions. Design validation evaluates the final product in real-world or simulated conditions to guarantee it fulfills user needs and intended use. Verification focuses on "building the device right," while validation emphasizes "building the right device" for patient safety and regulatory compliance.

Regulatory Requirements: Verification vs. Validation

Design verification confirms that medical device outputs meet specified design inputs through objective evidence, ensuring compliance with regulatory standards like ISO 13485 and FDA 21 CFR Part 820. Design validation, on the other hand, ensures the final product meets user needs and intended uses under actual or simulated conditions, as required by regulatory agencies to demonstrate product safety and efficacy. Both processes are critical regulatory requirements, where verification focuses on design accuracy and validation emphasizes real-world performance and usability.

Importance of Design Inputs and Outputs

Design validation and design verification are critical processes in medical device development that ensure compliance with regulatory standards and patient safety. Design inputs define essential requirements based on user needs and intended use, guiding the development process, while design outputs translate these requirements into tangible, testable specifications. Emphasizing clear, measurable design inputs and outputs enhances the accuracy of verification activities and validates that the final product meets clinical performance expectations.

Common Methods for Design Verification in Medical Devices

Common methods for design verification in medical devices include bench testing, software validation, and risk analysis to ensure the product meets specified design inputs. Verification activities often involve functional testing, electrical safety testing, and usability assessments conducted under controlled conditions. These methods confirm that the design outputs align accurately with design inputs before proceeding to clinical validation or regulatory submission.

Effective Strategies for Design Validation

Design validation ensures a medical device meets user needs and intended uses by testing in real-world scenarios, while design verification confirms the device meets specified design inputs through controlled evaluations. Effective strategies for design validation include utilizing simulated clinical environments, engaging end-users for usability testing, and incorporating risk-based assessment methodologies to identify potential failures before market release. These approaches enhance product reliability, regulatory compliance, and patient safety by addressing actual performance requirements beyond theoretical specifications.

Documentation Best Practices for Verification and Validation

Design verification ensures the medical device meets specified design requirements through objective evidence, while design validation confirms the device fulfills user needs and intended use in the actual environment. Effective documentation best practices for verification and validation include maintaining comprehensive traceability matrices, detailed test protocols, and clear records of test results and deviations. Adhering to regulatory standards such as ISO 13485 and FDA 21 CFR Part 820 mandates thorough documentation to support design control audits and device approval.

Avoiding Common Pitfalls in Design Verification and Validation

Design validation ensures the medical device meets user needs and intended uses through clinical evaluations and real-world testing, while design verification confirms the device meets specified design inputs via laboratory and bench tests. Common pitfalls in design verification include incomplete test coverage and inadequate traceability, which can lead to non-compliance and product failures. Implementing rigorous documentation practices and aligning verification activities with design inputs and risk management processes is essential to avoid these errors and ensure regulatory approval.

The Impact of Verification and Validation on FDA Approval

Design verification ensures that medical device products meet specified design requirements, while design validation confirms the device fulfills user needs and intended uses. Both processes are critical for FDA approval, as they provide documented evidence that the device is safe, effective, and compliant with regulatory standards. A robust verification and validation strategy reduces the risk of product recalls and accelerates market entry by demonstrating thorough risk management and quality control.

Design validation vs Design verification Infographic

productdif.com

productdif.com