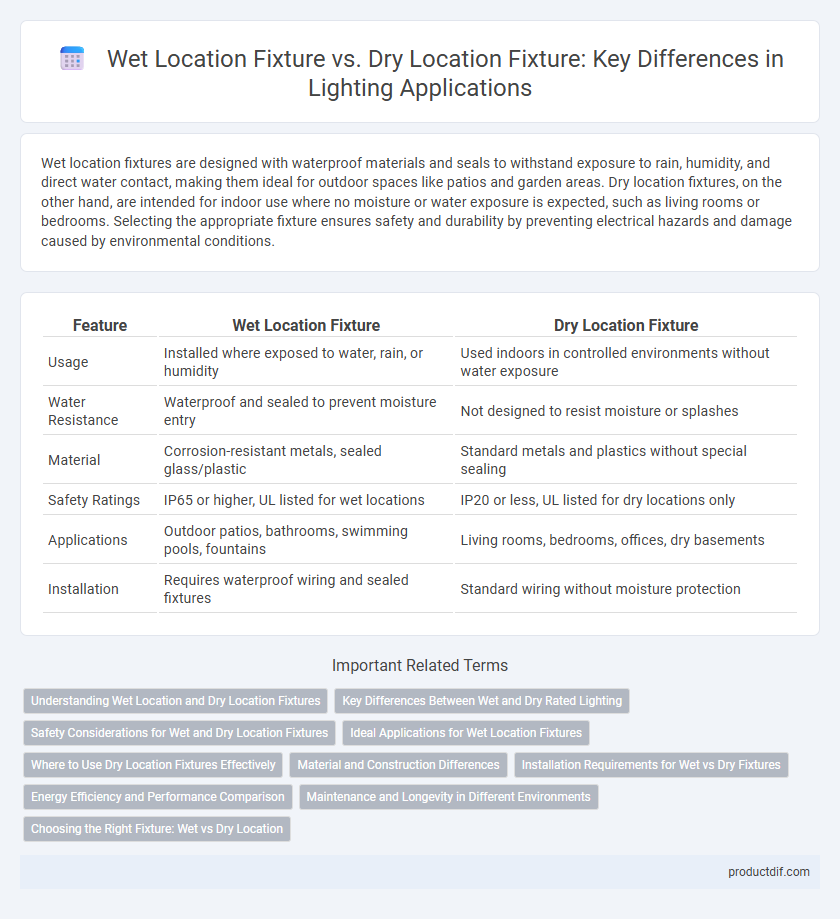

Wet location fixtures are designed with waterproof materials and seals to withstand exposure to rain, humidity, and direct water contact, making them ideal for outdoor spaces like patios and garden areas. Dry location fixtures, on the other hand, are intended for indoor use where no moisture or water exposure is expected, such as living rooms or bedrooms. Selecting the appropriate fixture ensures safety and durability by preventing electrical hazards and damage caused by environmental conditions.

Table of Comparison

| Feature | Wet Location Fixture | Dry Location Fixture |

|---|---|---|

| Usage | Installed where exposed to water, rain, or humidity | Used indoors in controlled environments without water exposure |

| Water Resistance | Waterproof and sealed to prevent moisture entry | Not designed to resist moisture or splashes |

| Material | Corrosion-resistant metals, sealed glass/plastic | Standard metals and plastics without special sealing |

| Safety Ratings | IP65 or higher, UL listed for wet locations | IP20 or less, UL listed for dry locations only |

| Applications | Outdoor patios, bathrooms, swimming pools, fountains | Living rooms, bedrooms, offices, dry basements |

| Installation | Requires waterproof wiring and sealed fixtures | Standard wiring without moisture protection |

Understanding Wet Location and Dry Location Fixtures

Wet location fixtures are specifically designed to withstand direct exposure to water, moisture, and adverse weather conditions, making them ideal for outdoor areas such as patios, gardens, or bathrooms. Dry location fixtures, on the other hand, are intended for indoor use where they remain protected from moisture and dampness, ensuring safety and longevity in controlled environments like living rooms or offices. Understanding the distinction between wet and dry location fixtures is crucial for selecting appropriate lighting solutions that comply with safety codes and enhance durability.

Key Differences Between Wet and Dry Rated Lighting

Wet location fixtures are designed with sealed housings and corrosion-resistant materials to withstand direct exposure to rain, snow, and moisture, ensuring safety and durability in outdoor environments. Dry location fixtures, by contrast, are intended for indoor use only where they are protected from water and excessive humidity, featuring ventilation and finish materials that are not waterproof. The key difference lies in their moisture protection standards, with wet rated fixtures meeting stringent requirements for water ingress prevention under the National Electrical Code (NEC) and UL certifications, while dry rated fixtures do not.

Safety Considerations for Wet and Dry Location Fixtures

Wet location fixtures feature sealed enclosures and corrosion-resistant materials to prevent water infiltration and electrical hazards, ensuring safe operation in damp or submerged environments. Dry location fixtures, designed without waterproof protection, prioritize ventilation and heat dissipation but must be installed away from moisture to maintain safety. Selecting the appropriate fixture based on the environment reduces risks of electrical shock, short circuits, and fixture damage, enhancing overall safety compliance.

Ideal Applications for Wet Location Fixtures

Wet location fixtures are specifically designed for environments exposed to moisture, making them ideal for outdoor areas such as patios, garden pathways, and poolside installations where water splashes or rain exposure occur. Their robust, waterproof construction ensures safety and durability in bathrooms, saunas, and covered porches, preventing electrical hazards caused by wet conditions. Using wet location fixtures in these settings enhances longevity and compliance with electrical codes focused on moisture protection.

Where to Use Dry Location Fixtures Effectively

Dry location lighting fixtures are designed for indoor spaces protected from moisture, such as living rooms, bedrooms, and offices, ensuring optimal safety and performance. These fixtures provide effective illumination without concern for water exposure, making them ideal for areas with controlled environments and low humidity. Choosing dry location fixtures in these settings maximizes durability and energy efficiency, avoiding potential damage from moisture.

Material and Construction Differences

Wet location fixtures feature corrosion-resistant materials such as stainless steel, brass, or specially coated metals, with sealed, watertight enclosures to prevent moisture ingress. Dry location fixtures utilize standard metals and plastics without special sealing, designed for environments free from water exposure. The construction of wet location fixtures emphasizes robust gaskets and molded seals to withstand humidity and direct contact with water, whereas dry location fixtures have simpler designs suited for indoor, low-moisture settings.

Installation Requirements for Wet vs Dry Fixtures

Wet location fixtures require specialized sealing, corrosion-resistant materials, and waterproof gaskets to prevent moisture ingress during installation, ensuring durability in environments exposed to rain, snow, or direct water contact. Dry location fixtures allow more flexible installation options with less stringent moisture protection standards, making them suitable for indoor or protected areas free from water exposure. Proper adherence to local electrical codes and manufacturer specifications is critical to guarantee safety and compliance for both wet and dry location fixture installations.

Energy Efficiency and Performance Comparison

Wet location lighting fixtures are designed with durable, waterproof materials and sealed enclosures that prevent moisture damage, maintaining optimal energy efficiency in damp or outdoor environments. Dry location fixtures, lacking such protective features, typically offer higher efficiency ratings indoors where moisture isn't a factor, allowing for better heat dissipation and longer-lasting performance. Comparing energy efficiency, wet location fixtures often use specialized LED technologies that balance durability and power consumption but may exhibit slightly lower luminous efficacy than dry location fixtures optimized for stable, dry conditions.

Maintenance and Longevity in Different Environments

Wet location fixtures are designed with sealed enclosures and corrosion-resistant materials to withstand moisture, dirt, and temperature fluctuations, significantly reducing maintenance needs and enhancing longevity in outdoor or humid environments. Dry location fixtures lack these protective features, making them more susceptible to damage from water exposure, requiring frequent inspections and replacements in damp conditions. Choosing the appropriate fixture type based on environmental exposure directly impacts maintenance frequency, operational lifespan, and overall safety of the lighting installation.

Choosing the Right Fixture: Wet vs Dry Location

Selecting the right lighting fixture depends on the installation environment, with wet location fixtures designed to withstand exposure to moisture, rain, and humidity, making them ideal for outdoor areas, bathrooms, and kitchens. Dry location fixtures are suitable for indoor spaces with minimal moisture, such as living rooms, bedrooms, and offices, ensuring safety and longevity where water exposure is unlikely. Properly categorizing fixtures by their UL or IP rating guarantees optimal performance and compliance with electrical safety standards.

Wet location fixture vs Dry location fixture Infographic

productdif.com

productdif.com