Platinum soldering requires higher temperatures and specialized equipment due to its dense structure and resistance to melting, making it more challenging than gold soldering. Gold soldering is more versatile and easier to perform at lower temperatures, allowing for a wider range of jewelry repairs and creations. Both techniques demand precision, but platinum soldering offers superior strength and durability for high-end pieces.

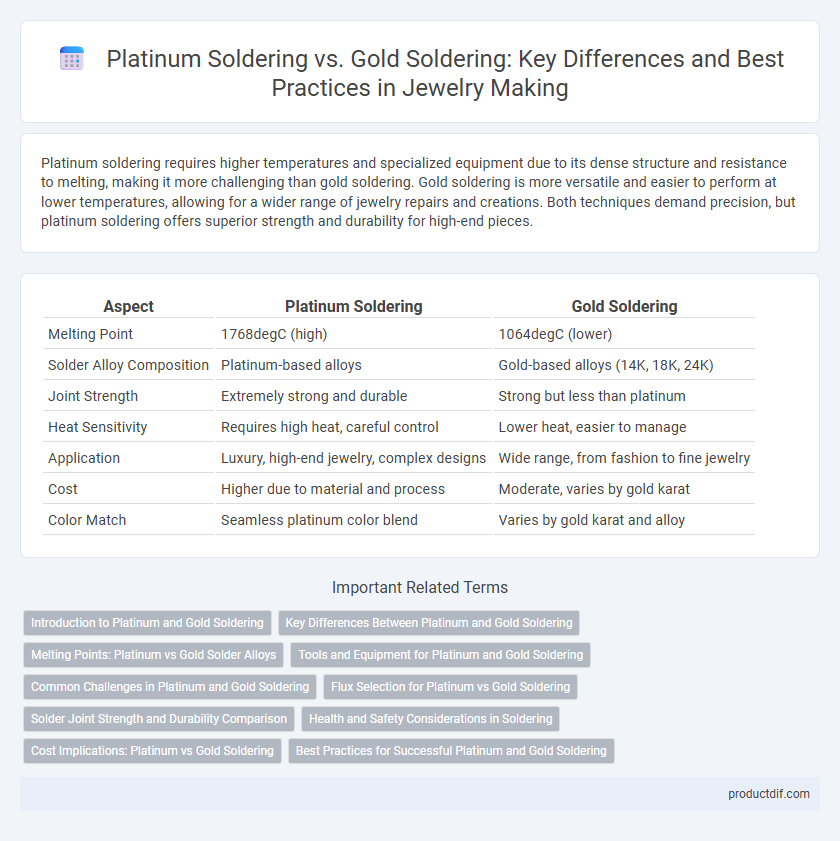

Table of Comparison

| Aspect | Platinum Soldering | Gold Soldering |

|---|---|---|

| Melting Point | 1768degC (high) | 1064degC (lower) |

| Solder Alloy Composition | Platinum-based alloys | Gold-based alloys (14K, 18K, 24K) |

| Joint Strength | Extremely strong and durable | Strong but less than platinum |

| Heat Sensitivity | Requires high heat, careful control | Lower heat, easier to manage |

| Application | Luxury, high-end jewelry, complex designs | Wide range, from fashion to fine jewelry |

| Cost | Higher due to material and process | Moderate, varies by gold karat |

| Color Match | Seamless platinum color blend | Varies by gold karat and alloy |

Introduction to Platinum and Gold Soldering

Platinum soldering requires higher temperatures, around 1,700degF to 1,900degF, compared to gold soldering, which typically occurs between 1,200degF and 1,300degF. Platinum solder alloys are specially formulated to match the metal's melting point and maintain strength, while gold solder blends vary to accommodate karat purity and color matching. Proper temperature control and flux selection are critical in both processes to ensure clean joints, prevent oxidation, and preserve the jewelry's aesthetic and structural integrity.

Key Differences Between Platinum and Gold Soldering

Platinum soldering requires higher temperatures, typically around 1200degC, compared to gold soldering which melts between 900degC to 1100degC, due to platinum's higher melting point. Platinum soldering demands specialized flux and inert gas environments like argon to prevent oxidation, whereas gold soldering is more forgiving and can often be performed in ambient air with standard flux. The strength and durability of platinum solder joints surpass those of gold solder due to platinum's superior corrosion resistance and hardness.

Melting Points: Platinum vs Gold Solder Alloys

Platinum soldering requires higher temperatures due to platinum's melting point around 1,768degC, compared to lower melting points of gold solder alloys typically ranging from 600degC to 1,000degC. The elevated melting point of platinum alloys demands specialized equipment and precise temperature control to avoid damage during soldering. Gold solder alloys offer greater versatility in temperature settings, making them more accessible for various jewelry applications.

Tools and Equipment for Platinum and Gold Soldering

Platinum soldering requires specialized tools such as an inert gas torch setup to prevent oxidation and a precise temperature-controlled furnace to handle its high melting point of approximately 1772degC, distinct from gold soldering which utilizes standard torches and relatively lower melting temperatures around 1064degC. Equipment for gold soldering often includes a standard jeweler's torch, fluxes, and a soldering pick, while platinum soldering mandates more advanced equipment like high-frequency induction heaters and a protective atmosphere setup to maintain the metal's integrity. The choice of tools directly impacts the quality and precision of soldering, with platinum demanding more rigorous temperature control and protective measures due to its unique physical properties.

Common Challenges in Platinum and Gold Soldering

Platinum soldering presents challenges due to its high melting point, requiring specialized solder and precise temperature control to avoid metal distortion or weakening. Gold soldering commonly struggles with color matching and alloy compatibility, as improper solder can cause visible seams or color mismatches in finished pieces. Both metals demand skilled artisanship and specific fluxes to ensure strong, seamless joints without compromising the jewelry's structural integrity.

Flux Selection for Platinum vs Gold Soldering

Flux selection is critical in platinum soldering due to its high melting point and sensitivity to oxidation, requiring specialized fluxes like borax-based or fluoroborate flux for effective joint protection and strong bonds. Gold soldering typically uses borax-based flux that facilitates smooth flow and prevents oxidation at lower melting temperatures, ensuring clean, precise joints. Choosing the correct flux for each metal optimizes solder flow, joint strength, and overall finish quality in fine jewelry craftsmanship.

Solder Joint Strength and Durability Comparison

Platinum soldering creates stronger and more durable solder joints compared to gold soldering, as platinum's higher melting point results in better heat resistance and joint integrity. Gold solder joints, while more malleable and easier to work with, tend to be less resistant to wear and mechanical stress over time. The molecular structure of platinum solder allows for enhanced bonding and reduced corrosion, making it ideal for high-stress and long-lasting jewelry pieces.

Health and Safety Considerations in Soldering

Platinum soldering requires higher temperatures, increasing the risk of burns and inhalation of harmful fumes, necessitating advanced ventilation and heat-resistant protective gear. Gold soldering typically involves lower temperatures and less toxic fluxes, reducing exposure to hazardous fumes but still demands adequate ventilation and protective eyewear to prevent eye injury. Both processes should implement strict safety protocols, including fume extraction systems and personal protective equipment, to minimize health risks associated with metal fumes and thermal hazards.

Cost Implications: Platinum vs Gold Soldering

Platinum soldering typically incurs higher costs due to the metal's higher melting point and the specialized expertise required, making it more labor-intensive compared to gold soldering. Gold soldering offers more affordable pricing as gold alloys melt at lower temperatures and allow for faster, less complex repairs or customizations. Budget considerations often lead jewelry professionals to prefer gold soldering for cost-effective solutions, while platinum soldering is reserved for high-end pieces demanding exceptional durability and finish.

Best Practices for Successful Platinum and Gold Soldering

Platinum soldering requires high temperatures, precise flux application, and compatible platinum solders to ensure strong, clean joints, with careful control to prevent metal distortion or contamination. Gold soldering benefits from selecting the correct karat and color-matched solder, maintaining proper flame temperature, and using borax or other fluxes to prevent oxidation and ensure smooth metal flow. Both metals demand meticulous surface preparation and post-soldering cleaning to achieve durable, aesthetically appealing jewelry pieces.

Platinum Soldering vs Gold Soldering Infographic

productdif.com

productdif.com