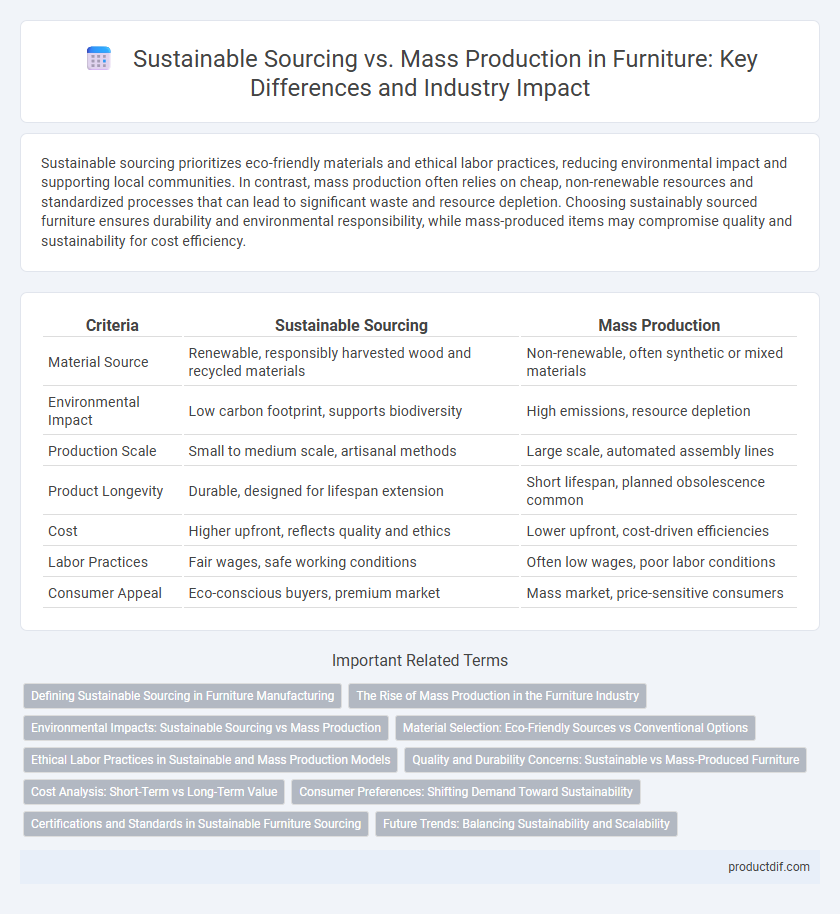

Sustainable sourcing prioritizes eco-friendly materials and ethical labor practices, reducing environmental impact and supporting local communities. In contrast, mass production often relies on cheap, non-renewable resources and standardized processes that can lead to significant waste and resource depletion. Choosing sustainably sourced furniture ensures durability and environmental responsibility, while mass-produced items may compromise quality and sustainability for cost efficiency.

Table of Comparison

| Criteria | Sustainable Sourcing | Mass Production |

|---|---|---|

| Material Source | Renewable, responsibly harvested wood and recycled materials | Non-renewable, often synthetic or mixed materials |

| Environmental Impact | Low carbon footprint, supports biodiversity | High emissions, resource depletion |

| Production Scale | Small to medium scale, artisanal methods | Large scale, automated assembly lines |

| Product Longevity | Durable, designed for lifespan extension | Short lifespan, planned obsolescence common |

| Cost | Higher upfront, reflects quality and ethics | Lower upfront, cost-driven efficiencies |

| Labor Practices | Fair wages, safe working conditions | Often low wages, poor labor conditions |

| Consumer Appeal | Eco-conscious buyers, premium market | Mass market, price-sensitive consumers |

Defining Sustainable Sourcing in Furniture Manufacturing

Sustainable sourcing in furniture manufacturing emphasizes using renewable, ethically harvested materials that minimize environmental impact and support fair labor practices. This approach prioritizes certified wood, recycled metals, and biodegradable textiles, ensuring resource conservation and reduced carbon footprint. Unlike mass production, sustainable sourcing aligns with eco-conscious consumer demands and long-term ecological balance.

The Rise of Mass Production in the Furniture Industry

Mass production in the furniture industry has surged due to advancements in automated manufacturing and global supply chains, enabling rapid scale and cost efficiency. This approach prioritizes uniformity and affordability, often relying on non-renewable materials and extensive resource consumption. The environmental impact and ethical concerns associated with mass-produced furniture have driven a growing demand for sustainable sourcing practices.

Environmental Impacts: Sustainable Sourcing vs Mass Production

Sustainable sourcing in furniture manufacturing significantly reduces environmental impacts by utilizing responsibly harvested materials and minimizing waste through eco-friendly production techniques. Mass production often relies on non-renewable resources, excessive energy consumption, and generates higher levels of pollution and deforestation. Choosing sustainable sourcing supports biodiversity, lowers carbon footprints, and promotes long-term ecological balance in the furniture industry.

Material Selection: Eco-Friendly Sources vs Conventional Options

Sustainable sourcing in furniture prioritizes eco-friendly materials such as reclaimed wood, bamboo, and recycled metals, reducing environmental impact and promoting renewable resources. Mass production often relies on conventional materials like non-certified hardwoods, particleboard, and synthetic fabrics that contribute to deforestation and higher carbon footprints. Choosing sustainable materials enhances durability and supports ethical supply chains while minimizing waste and pollution.

Ethical Labor Practices in Sustainable and Mass Production Models

Ethical labor practices in sustainable furniture sourcing prioritize fair wages, safe working conditions, and workers' rights, distinguishing them from often exploitative mass production models. Sustainable sourcing emphasizes transparency and accountability throughout the supply chain, ensuring that artisans and factory workers receive equitable treatment. Mass production, driven by cost-cutting and high-volume output, frequently overlooks labor ethics, leading to unsafe work environments and unfair employment terms.

Quality and Durability Concerns: Sustainable vs Mass-Produced Furniture

Sustainable sourcing in furniture manufacturing emphasizes high-quality materials and craftsmanship, resulting in pieces known for superior durability and long-term value. Mass-produced furniture often relies on cheaper, less durable components to meet large-scale demand, which can compromise structural integrity and lifespan. Consumers seeking longevity and environmental responsibility benefit more from sustainably sourced furniture due to its enhanced quality and reduced ecological impact.

Cost Analysis: Short-Term vs Long-Term Value

Sustainable sourcing in furniture manufacturing often incurs higher initial costs due to ethical material procurement and eco-friendly processes, contrasting with the lower upfront expenses typical of mass production. Short-term savings in mass production can lead to increased long-term costs from environmental impact, reduced product lifespan, and potential regulatory penalties. Investing in sustainable sourcing ultimately enhances long-term value by promoting durability, brand reputation, and compliance with evolving environmental standards.

Consumer Preferences: Shifting Demand Toward Sustainability

Consumer preferences in the furniture industry increasingly favor sustainable sourcing over mass production due to growing environmental awareness and ethical considerations. Demand for eco-friendly materials such as reclaimed wood, bamboo, and recycled metals reflects a shift toward products with lower carbon footprints and transparent supply chains. Brands that prioritize certified sustainable practices and durability attract environmentally conscious buyers willing to invest in quality over quantity.

Certifications and Standards in Sustainable Furniture Sourcing

Sustainable furniture sourcing relies heavily on certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) to ensure responsible forest management and legal wood procurement. These standards verify that materials come from renewable sources with minimal environmental impact, promoting biodiversity conservation and social responsibility. In contrast, mass production often lacks such certifications, leading to unchecked deforestation and higher carbon footprints.

Future Trends: Balancing Sustainability and Scalability

Future trends in furniture emphasize balancing sustainability and scalability through innovative materials and production techniques. Embracing renewable resources and circular design principles reduces environmental impact while meeting growing demand. Advanced manufacturing technologies such as 3D printing enable efficient mass production with minimized waste, supporting eco-friendly scalability goals.

Sustainable Sourcing vs Mass Production Infographic

productdif.com

productdif.com