Knock-down joinery offers easy assembly and disassembly, making it ideal for flat-pack furniture and frequent moves, while mortise-and-tenon joints provide superior strength and durability for long-lasting construction. Knock-down fittings prioritize convenience and modularity, whereas mortise-and-tenon craftsmanship emphasizes traditional woodworking techniques and structural integrity. Choosing between the two depends on the balance between portability and robust, timeless design required for the furniture piece.

Table of Comparison

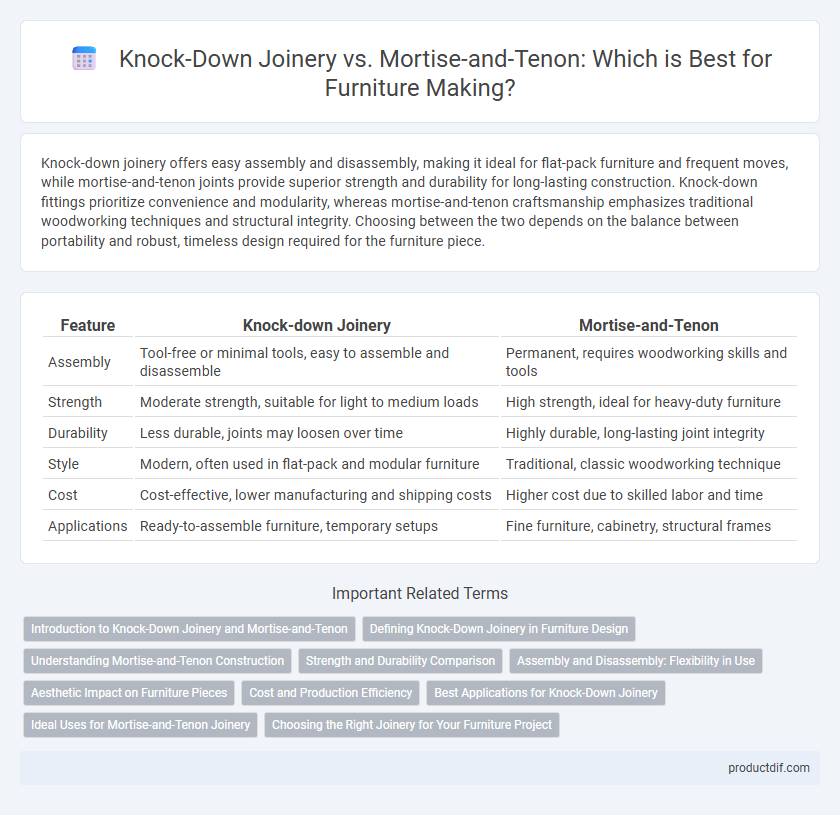

| Feature | Knock-down Joinery | Mortise-and-Tenon |

|---|---|---|

| Assembly | Tool-free or minimal tools, easy to assemble and disassemble | Permanent, requires woodworking skills and tools |

| Strength | Moderate strength, suitable for light to medium loads | High strength, ideal for heavy-duty furniture |

| Durability | Less durable, joints may loosen over time | Highly durable, long-lasting joint integrity |

| Style | Modern, often used in flat-pack and modular furniture | Traditional, classic woodworking technique |

| Cost | Cost-effective, lower manufacturing and shipping costs | Higher cost due to skilled labor and time |

| Applications | Ready-to-assemble furniture, temporary setups | Fine furniture, cabinetry, structural frames |

Introduction to Knock-Down Joinery and Mortise-and-Tenon

Knock-down joinery offers furniture that can be easily assembled and disassembled without tools, making it ideal for portability and space-saving solutions. Mortise-and-tenon joinery provides a traditional, strong, and durable connection by fitting a tenon into a corresponding mortise, often used in high-quality, handcrafted furniture. Both methods serve distinct purposes, balancing convenience with structural integrity in furniture design.

Defining Knock-Down Joinery in Furniture Design

Knock-down joinery in furniture design refers to connections that allow disassembly and reassembly without damaging the components, often using bolts, screws, or specialized connectors. This method enhances portability and ease of transport, making it ideal for flat-pack and modular furniture solutions. Knock-down joinery differs from traditional mortise-and-tenon by prioritizing convenience and flexibility over permanent, interlocking wood joints.

Understanding Mortise-and-Tenon Construction

Mortise-and-tenon construction is a traditional woodworking technique that involves fitting a protruding tenon into a corresponding mortise hole to create strong, durable joints commonly used in furniture making. This method provides superior stability and load-bearing capacity compared to knock-down joinery, which relies on mechanical fasteners for assembly. Understanding mortise-and-tenon joinery is essential for crafting high-quality furniture pieces that require long-lasting structural integrity and aesthetic appeal.

Strength and Durability Comparison

Knock-down joinery offers ease of assembly and disassembly but typically provides less strength and long-term durability compared to mortise-and-tenon joints. Mortise-and-tenon joinery creates a robust mechanical interlock that withstands heavy loads and resist shear forces, making it ideal for high-stress furniture components. The dense wood-to-wood contact and glue surface area in mortise-and-tenon joints deliver superior longevity and structural integrity over the modular design of knock-down fittings.

Assembly and Disassembly: Flexibility in Use

Knock-down joinery offers superior flexibility in assembly and disassembly, making it ideal for furniture that requires frequent relocation or storage. Mortise-and-tenon joints provide a rigid, permanent connection, ensuring stability but limiting ease of disassembly. Furniture designs prioritizing modularity often favor knock-down joinery for enhanced user convenience and adaptability.

Aesthetic Impact on Furniture Pieces

Knock-down joinery offers a modern, minimalist aesthetic with visible hardware that emphasizes functionality and ease of assembly. Mortise-and-tenon joinery provides a traditional, seamless look with concealed joints that enhance the craftsmanship and elegance of furniture pieces. Choosing between these methods significantly influences the visual appeal and design integrity of the final product.

Cost and Production Efficiency

Knock-down joinery offers significant cost savings and production efficiency due to its simpler assembly process and reduced need for skilled labor, making it ideal for mass-produced furniture. Mortise-and-tenon joints, while providing superior durability and strength, involve more labor-intensive craftsmanship and higher material costs, leading to longer production times and increased expenses. Manufacturers prioritize knock-down joinery in budget-conscious projects focused on quick assembly and flat-pack shipping.

Best Applications for Knock-Down Joinery

Knock-down joinery is best applied in furniture designed for portability and easy assembly, such as flat-pack wardrobes, office desks, and modular shelving units. Its quick disassembly and reassembly capabilities make it ideal for rental properties, trade shows, and small living spaces where frequent moves or reconfigurations occur. This joinery technique also suits cost-effective mass production, reducing shipping costs and minimizing damage during transit.

Ideal Uses for Mortise-and-Tenon Joinery

Mortise-and-tenon joinery excels in creating strong, durable connections ideal for load-bearing furniture like dining tables, chairs, and bed frames. This technique provides superior resistance to shear and tension forces, making it optimal for structural components subjected to frequent stress. Its precision and stability make it the preferred choice for heirloom-quality pieces requiring long-term durability.

Choosing the Right Joinery for Your Furniture Project

Selecting the right joinery technique significantly influences the durability and aesthetics of furniture. Knock-down joinery offers easy assembly and disassembly, making it ideal for flat-pack furniture and modular designs, while mortise-and-tenon joints provide superior strength and traditional craftsmanship suited for heirloom-quality pieces. Evaluating factors such as load-bearing requirements, intended use, and desired finish helps determine the optimal joinery method for a specific furniture project.

Knock-down joinery vs mortise-and-tenon Infographic

productdif.com

productdif.com