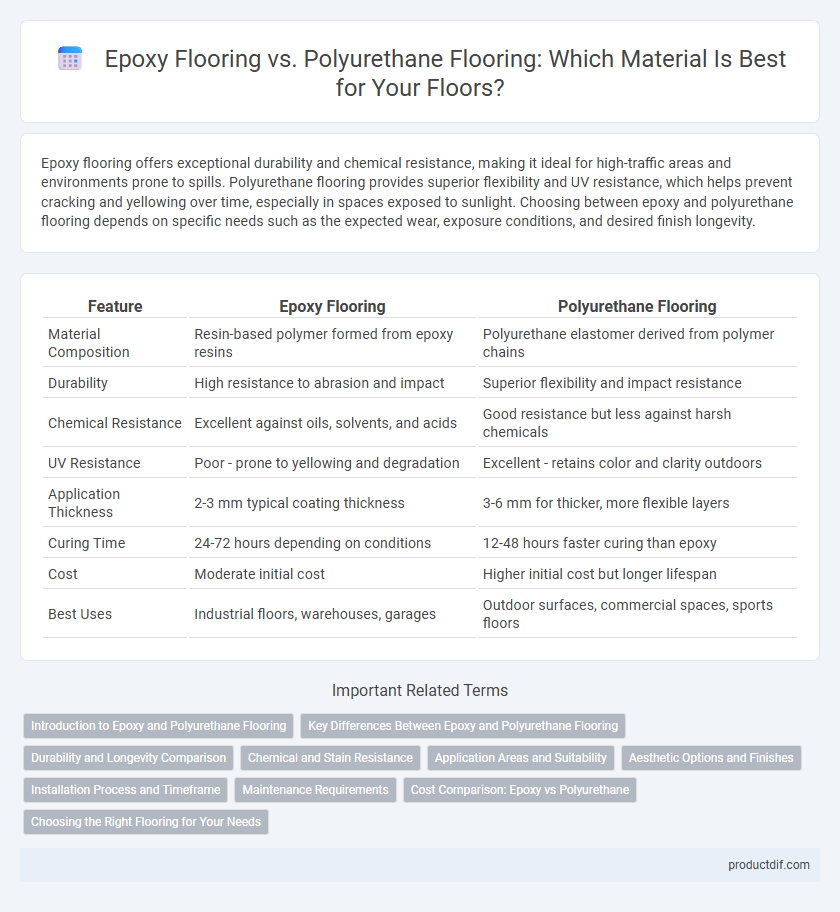

Epoxy flooring offers exceptional durability and chemical resistance, making it ideal for high-traffic areas and environments prone to spills. Polyurethane flooring provides superior flexibility and UV resistance, which helps prevent cracking and yellowing over time, especially in spaces exposed to sunlight. Choosing between epoxy and polyurethane flooring depends on specific needs such as the expected wear, exposure conditions, and desired finish longevity.

Table of Comparison

| Feature | Epoxy Flooring | Polyurethane Flooring |

|---|---|---|

| Material Composition | Resin-based polymer formed from epoxy resins | Polyurethane elastomer derived from polymer chains |

| Durability | High resistance to abrasion and impact | Superior flexibility and impact resistance |

| Chemical Resistance | Excellent against oils, solvents, and acids | Good resistance but less against harsh chemicals |

| UV Resistance | Poor - prone to yellowing and degradation | Excellent - retains color and clarity outdoors |

| Application Thickness | 2-3 mm typical coating thickness | 3-6 mm for thicker, more flexible layers |

| Curing Time | 24-72 hours depending on conditions | 12-48 hours faster curing than epoxy |

| Cost | Moderate initial cost | Higher initial cost but longer lifespan |

| Best Uses | Industrial floors, warehouses, garages | Outdoor surfaces, commercial spaces, sports floors |

Introduction to Epoxy and Polyurethane Flooring

Epoxy flooring is a thermosetting resin known for its high durability, chemical resistance, and seamless finish, making it ideal for industrial and commercial applications. Polyurethane flooring offers superior flexibility, UV resistance, and abrasion resistance, often favored in environments with frequent temperature fluctuations and outdoor exposure. Both materials provide robust protective coatings but differ significantly in composition, performance characteristics, and suitability for specific flooring needs.

Key Differences Between Epoxy and Polyurethane Flooring

Epoxy flooring is known for its exceptional hardness and chemical resistance, making it ideal for industrial environments, while polyurethane flooring offers superior flexibility and UV resistance, suitable for areas exposed to sunlight. Epoxy creates a rigid, durable surface that withstands heavy impact and abrasion, whereas polyurethane provides better elasticity, reducing the risk of cracks and discoloration over time. The curing time for epoxy is typically faster, but polyurethane flooring shines with its superior resistance to yellowing and moisture.

Durability and Longevity Comparison

Epoxy flooring offers exceptional chemical resistance and hardness, making it highly durable in industrial settings, while polyurethane flooring provides superior flexibility and UV resistance, enhancing its longevity in areas with temperature fluctuations and sunlight exposure. Polyurethane's ability to withstand abrasion and impact without cracking extends its lifespan beyond epoxy in dynamic environments. Both materials are long-lasting, but polyurethane flooring generally outperforms epoxy in durability under varying environmental conditions.

Chemical and Stain Resistance

Epoxy flooring offers exceptional chemical resistance, making it ideal for industrial settings where exposure to harsh chemicals and solvents is frequent. Polyurethane flooring provides superior stain resistance and flexibility, enhancing durability against oils, fats, and UV exposure, which helps prevent discoloration and surface degradation. Both materials deliver reliable protection, but epoxy specializes in resisting aggressive chemicals while polyurethane excels in resisting stains and maintaining aesthetic appeal under heavy wear.

Application Areas and Suitability

Epoxy flooring excels in industrial and commercial settings such as warehouses, factories, and garages due to its high durability, chemical resistance, and strong adhesion to concrete surfaces. Polyurethane flooring offers superior flexibility and UV resistance, making it ideal for areas exposed to sunlight and temperature fluctuations, such as outdoor patios, sports facilities, and hospitals. Choosing between epoxy and polyurethane flooring depends on specific application requirements, with epoxy suited for heavy-duty use and polyurethane preferred for comfort and extended exposure to environmental elements.

Aesthetic Options and Finishes

Epoxy flooring offers a wide range of aesthetic options including high-gloss finishes, metallic effects, and custom color blending that allows for impressive design versatility in commercial and residential spaces. Polyurethane flooring stands out with its UV-resistant properties, maintaining color vibrancy and offering a matte to semi-gloss finish that resists yellowing over time. Both materials provide seamless, durable surfaces, but epoxy is often chosen for its artistic finish variety while polyurethane excels in long-lasting aesthetic appeal under sunlight exposure.

Installation Process and Timeframe

Epoxy flooring installation involves surface preparation, primer application, followed by multiple epoxy coat layers, typically requiring 24 to 72 hours for full curing, depending on ambient conditions. Polyurethane flooring demands a similar surface prep but offers faster curing times, often completing installation within 12 to 24 hours, enhancing project turnaround. Both materials require professional surface assessment, but polyurethane's quicker set time can minimize downtime in commercial and industrial settings.

Maintenance Requirements

Epoxy flooring requires regular cleaning with mild detergents and periodic reapplication of sealants to maintain its glossy finish and resist chemical stains. Polyurethane flooring demonstrates superior resistance to abrasion and UV rays, reducing the need for frequent maintenance and preventing yellowing over time. Both materials benefit from prompt spill cleanup, but polyurethane's elasticity offers enhanced durability in high-traffic or industrial environments with minimal upkeep.

Cost Comparison: Epoxy vs Polyurethane

Epoxy flooring generally costs between $3 to $12 per square foot, making it a more budget-friendly option for large commercial and industrial spaces. Polyurethane flooring tends to be priced higher, ranging from $6 to $15 per square foot, due to its superior flexibility and UV resistance. Maintenance expenses for polyurethane can also be lower over time because of its durability, despite the initially higher installation cost.

Choosing the Right Flooring for Your Needs

Epoxy flooring offers high durability and chemical resistance, making it ideal for industrial and commercial spaces with heavy traffic and exposure to harsh substances. Polyurethane flooring provides superior flexibility, UV resistance, and a smoother finish, suitable for areas requiring comfort underfoot and aesthetic appeal such as residential or retail environments. Assessing specific needs like durability, exposure conditions, and maintenance requirements ensures the right choice between epoxy and polyurethane flooring solutions.

Epoxy Flooring vs Polyurethane Flooring Infographic

productdif.com

productdif.com