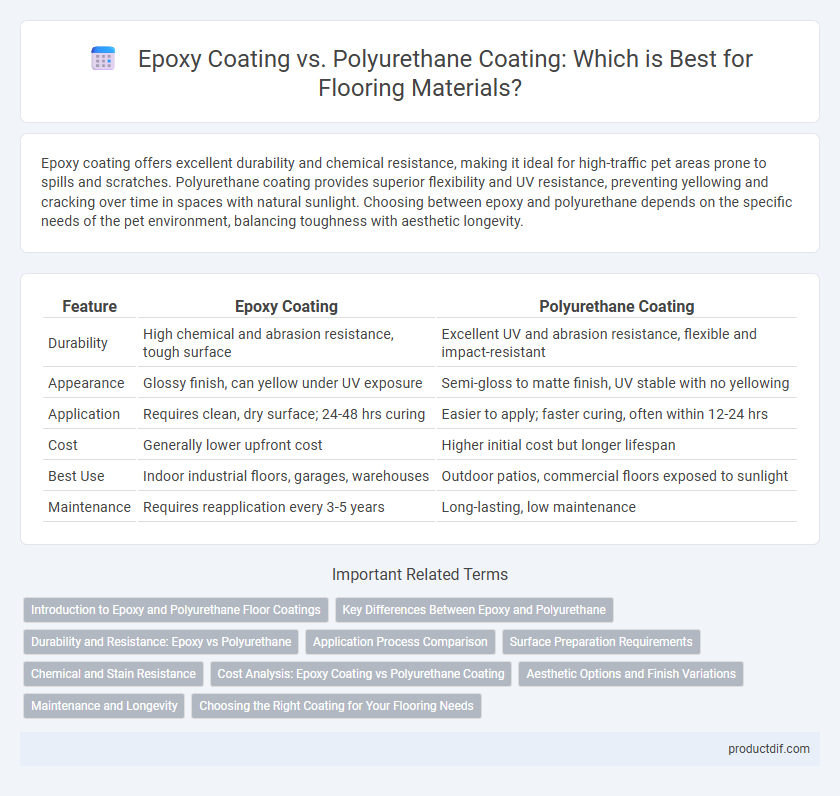

Epoxy coating offers excellent durability and chemical resistance, making it ideal for high-traffic pet areas prone to spills and scratches. Polyurethane coating provides superior flexibility and UV resistance, preventing yellowing and cracking over time in spaces with natural sunlight. Choosing between epoxy and polyurethane depends on the specific needs of the pet environment, balancing toughness with aesthetic longevity.

Table of Comparison

| Feature | Epoxy Coating | Polyurethane Coating |

|---|---|---|

| Durability | High chemical and abrasion resistance, tough surface | Excellent UV and abrasion resistance, flexible and impact-resistant |

| Appearance | Glossy finish, can yellow under UV exposure | Semi-gloss to matte finish, UV stable with no yellowing |

| Application | Requires clean, dry surface; 24-48 hrs curing | Easier to apply; faster curing, often within 12-24 hrs |

| Cost | Generally lower upfront cost | Higher initial cost but longer lifespan |

| Best Use | Indoor industrial floors, garages, warehouses | Outdoor patios, commercial floors exposed to sunlight |

| Maintenance | Requires reapplication every 3-5 years | Long-lasting, low maintenance |

Introduction to Epoxy and Polyurethane Floor Coatings

Epoxy floor coatings consist of a resin and hardener that chemically react to form a durable, rigid surface known for exceptional adhesion and chemical resistance. Polyurethane floor coatings are composed of polymer chains that create a flexible, UV-resistant layer, offering superior abrasion resistance and elasticity. Both coatings enhance floor durability but differ in flexibility, chemical resistance, and application suitability.

Key Differences Between Epoxy and Polyurethane

Epoxy coating offers superior adhesion and chemical resistance, making it ideal for industrial flooring, while polyurethane coating excels in flexibility and UV resistance, suited for areas exposed to sunlight. Epoxy hardens to a rigid finish prone to cracking under heavy traffic, whereas polyurethane remains elastic, reducing wear from impact and abrasion. Cost-wise, epoxy is generally more affordable but less durable in outdoor conditions compared to the longer-lasting polyurethane alternatives.

Durability and Resistance: Epoxy vs Polyurethane

Epoxy coatings offer superior hardness and chemical resistance, making them ideal for industrial environments with heavy traffic and exposure to solvents or oils. Polyurethane coatings provide enhanced flexibility and UV resistance, which prevents cracking and yellowing in areas with direct sunlight or temperature fluctuations. Both materials deliver strong durability, but epoxy excels in abrasion resistance while polyurethane outperforms in impact resistance and weather durability.

Application Process Comparison

Epoxy coatings require thorough surface preparation, including cleaning and etching, before applying multiple layers that cure over 24 to 72 hours for a durable bond. Polyurethane coatings involve a simpler application process with fewer layers, offering faster drying times and superior UV resistance suitable for environments exposed to sunlight. Both coatings demand precise temperature and humidity control during application to ensure optimal adhesion and longevity.

Surface Preparation Requirements

Surface preparation for epoxy coating demands meticulous cleaning and often mechanical abrasion to ensure strong adhesion and prevent peeling. Polyurethane coating requires a similarly clean and dry substrate but is generally more forgiving with minor surface imperfections due to its flexibility. Proper surface priming is critical for both coatings to enhance durability and maximize lifespan on concrete or metal surfaces.

Chemical and Stain Resistance

Epoxy coatings exhibit superior chemical resistance against acids, alkalis, and solvents, making them ideal for industrial environments with frequent chemical exposure. Polyurethane coatings provide excellent stain resistance and maintain flexibility under temperature fluctuations, reducing the risk of cracking and discoloration. Both coatings offer durable protection, but epoxy excels in harsh chemical conditions while polyurethane is preferred for maintaining aesthetic appeal in areas prone to staining.

Cost Analysis: Epoxy Coating vs Polyurethane Coating

Epoxy coating generally costs between $3 to $12 per square foot, making it a more budget-friendly option for industrial and residential flooring, while polyurethane coating ranges from $6 to $15 per square foot due to its superior flexibility and UV resistance. Despite higher upfront costs, polyurethane often reduces long-term maintenance expenses because of its enhanced durability against abrasion and chemical exposure. Choosing between epoxy and polyurethane coatings requires evaluating initial investment against lifecycle performance and specific application requirements.

Aesthetic Options and Finish Variations

Epoxy coating offers a high-gloss, durable finish with a range of color options, including metallic and flake designs, creating a vibrant and seamless look ideal for commercial and residential spaces. Polyurethane coating provides a more flexible finish with satin to high-gloss sheens, excelling in UV resistance and clarity, making it suitable for areas exposed to sunlight and wear. Both coatings allow for customization, but epoxy is favored for rich, decorative effects, while polyurethane emphasizes long-lasting flexibility and gloss retention.

Maintenance and Longevity

Epoxy coating offers durable protection with excellent chemical resistance but typically requires reapplication every 3 to 5 years due to wear and UV sensitivity. Polyurethane coating provides superior abrasion resistance and UV stability, extending maintenance intervals to 5 to 10 years while maintaining gloss and flexibility. Both coatings benefit from routine cleaning, but polyurethane's elasticity better resists cracking and yellowing over time, enhancing overall longevity in high-traffic environments.

Choosing the Right Coating for Your Flooring Needs

Epoxy coating offers superior chemical resistance and high durability, making it ideal for industrial spaces with heavy foot traffic and machinery. Polyurethane coating provides excellent UV resistance and flexibility, suitable for areas exposed to sunlight or where slight floor movement occurs. Selecting the right coating hinges on factors such as environmental exposure, mechanical stress, and required finish longevity.

Epoxy Coating vs Polyurethane Coating Infographic

productdif.com

productdif.com