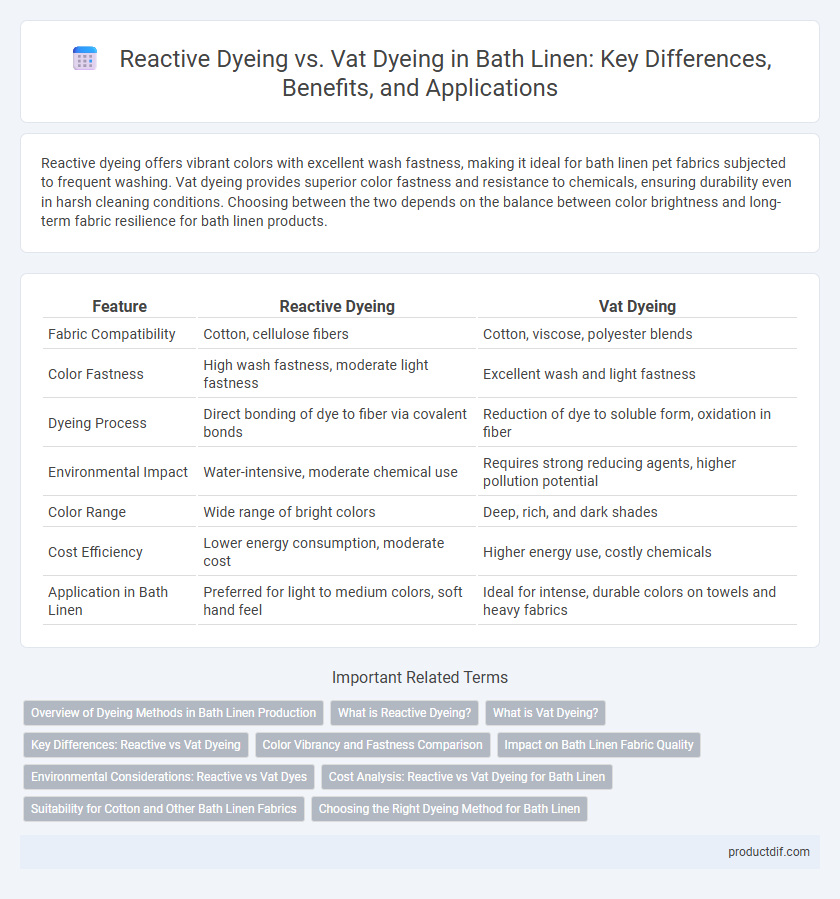

Reactive dyeing offers vibrant colors with excellent wash fastness, making it ideal for bath linen pet fabrics subjected to frequent washing. Vat dyeing provides superior color fastness and resistance to chemicals, ensuring durability even in harsh cleaning conditions. Choosing between the two depends on the balance between color brightness and long-term fabric resilience for bath linen products.

Table of Comparison

| Feature | Reactive Dyeing | Vat Dyeing |

|---|---|---|

| Fabric Compatibility | Cotton, cellulose fibers | Cotton, viscose, polyester blends |

| Color Fastness | High wash fastness, moderate light fastness | Excellent wash and light fastness |

| Dyeing Process | Direct bonding of dye to fiber via covalent bonds | Reduction of dye to soluble form, oxidation in fiber |

| Environmental Impact | Water-intensive, moderate chemical use | Requires strong reducing agents, higher pollution potential |

| Color Range | Wide range of bright colors | Deep, rich, and dark shades |

| Cost Efficiency | Lower energy consumption, moderate cost | Higher energy use, costly chemicals |

| Application in Bath Linen | Preferred for light to medium colors, soft hand feel | Ideal for intense, durable colors on towels and heavy fabrics |

Overview of Dyeing Methods in Bath Linen Production

Reactive dyeing in bath linen production offers bright, vivid colors with excellent colorfastness and eco-friendly water-based processing, ideal for natural fibers like cotton. Vat dyeing provides superior color durability and resistance to washing and light, making it suitable for heavy-use bath linens, though it requires complex chemical reduction and oxidation steps. Both methods play crucial roles in achieving high-quality, long-lasting bath linens with specific performance attributes.

What is Reactive Dyeing?

Reactive dyeing is a textile coloring process where dyes form a covalent bond with cellulose fibers, ensuring vibrant, long-lasting colors ideal for bath linens like towels and bathrobes. This method offers excellent color fastness to washing and light, making it a preferred choice for durable and high-quality bath textiles. Reactive dyes are water-soluble and typically applied at moderate temperatures, enhancing fabric softness and color uniformity in bath linen products.

What is Vat Dyeing?

Vat dyeing is a textile dyeing process used to produce vibrant, colorfast hues on bath linen, involving the reduction of insoluble vat dyes into a soluble form that penetrates fibers before oxidation restores the dye's insolubility. This method offers superior color durability and excellent resistance to washing and light, making it ideal for high-quality towels and bathrobes. Compared to reactive dyeing, vat dyeing provides deeper shades and enhanced longevity but requires more complex handling and processing conditions.

Key Differences: Reactive vs Vat Dyeing

Reactive dyeing chemically bonds dye molecules to the cellulose fibers in bath linen, resulting in vibrant, colorfast fabrics with excellent wash and light fastness. Vat dyeing involves insoluble dyes that are chemically reduced to a soluble form, allowing deep penetration into fibers, producing highly durable and colorfast bath linens with superior resistance to washing and light exposure. Reactive dyes are typically used for brighter shades on cotton-based textiles, while vat dyes excel in producing darker, more resistant colors on heavy-duty bath linens.

Color Vibrancy and Fastness Comparison

Reactive dyeing offers exceptional color vibrancy and excellent wash fastness, making it ideal for bath linen that requires bright, long-lasting hues. Vat dyeing provides superior light and chemical fastness, ensuring durability even after repeated exposure to sunlight and detergents. While reactive dyes excel in brilliance and eco-friendliness, vat dyes guarantee color retention under harsh conditions, making both suitable depending on the bath linen's usage environment.

Impact on Bath Linen Fabric Quality

Reactive dyeing enhances bath linen fabric quality by providing vibrant colors with excellent wash and light fastness, preserving the softness and absorbency essential for luxurious towels. Vat dyeing offers superior color durability and resistance to fading, but the process can sometimes reduce fabric softness, affecting the plush feel of bath linens. Selecting between reactive and vat dyeing depends on balancing colorfastness with maintaining the fabric's innate comfort and absorbency.

Environmental Considerations: Reactive vs Vat Dyes

Reactive dyeing of bath linen is more environmentally sustainable due to lower water and chemical consumption, and it generates less hazardous wastewater compared to vat dyeing. Vat dyeing involves strong reducing agents and alkalis that produce toxic effluents requiring extensive treatment to mitigate environmental impact. The biodegradability of reactive dyes and lower energy usage further enhance their eco-friendly profile in textile processing.

Cost Analysis: Reactive vs Vat Dyeing for Bath Linen

Reactive dyeing for bath linen offers lower initial equipment costs and simpler processing, making it cost-effective for small to medium-scale production. Vat dyeing involves higher setup expenses and longer processing times but provides superior colorfastness and durability, which can reduce replacement costs in high-use environments. Overall, reactive dyeing minimizes upfront investment, while vat dyeing delivers long-term value through enhanced fabric longevity.

Suitability for Cotton and Other Bath Linen Fabrics

Reactive dyeing offers excellent colorfastness and vibrant hues for cotton bath linen, making it highly suitable for towels and bathrobes due to strong fiber-dye bonding. Vat dyeing provides superior wash and light fastness, ideal for fabrics like linen and viscose used in luxury bath linens demanding long-lasting durability. Both methods cater to different fabric properties, with reactive dyes preferred for easy dyeing of cellulose fibers and vat dyes for deep, rich colors on more resilient materials.

Choosing the Right Dyeing Method for Bath Linen

Selecting the right dyeing method for bath linen hinges on fabric type, colorfastness, and environmental impact. Reactive dyeing offers vibrant colors with excellent wash-fastness on cellulosic fibers, ideal for cotton towels, while vat dyeing provides superior durability and resistance to fading, suitable for heavier or blended textiles. Consider reactive dyeing for energy-efficient, eco-friendly production, whereas vat dyeing excels in achieving deep, rich hues and long-lasting performance under frequent washing conditions.

Reactive dyeing vs Vat dyeing Infographic

productdif.com

productdif.com