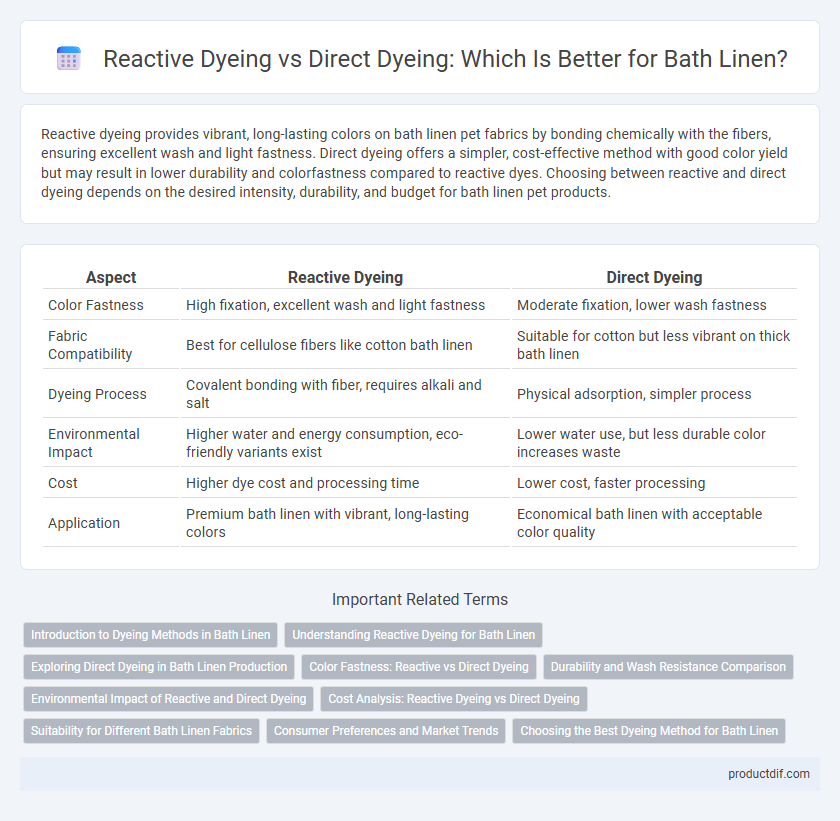

Reactive dyeing provides vibrant, long-lasting colors on bath linen pet fabrics by bonding chemically with the fibers, ensuring excellent wash and light fastness. Direct dyeing offers a simpler, cost-effective method with good color yield but may result in lower durability and colorfastness compared to reactive dyes. Choosing between reactive and direct dyeing depends on the desired intensity, durability, and budget for bath linen pet products.

Table of Comparison

| Aspect | Reactive Dyeing | Direct Dyeing |

|---|---|---|

| Color Fastness | High fixation, excellent wash and light fastness | Moderate fixation, lower wash fastness |

| Fabric Compatibility | Best for cellulose fibers like cotton bath linen | Suitable for cotton but less vibrant on thick bath linen |

| Dyeing Process | Covalent bonding with fiber, requires alkali and salt | Physical adsorption, simpler process |

| Environmental Impact | Higher water and energy consumption, eco-friendly variants exist | Lower water use, but less durable color increases waste |

| Cost | Higher dye cost and processing time | Lower cost, faster processing |

| Application | Premium bath linen with vibrant, long-lasting colors | Economical bath linen with acceptable color quality |

Introduction to Dyeing Methods in Bath Linen

Reactive dyeing in bath linen offers strong colorfastness and vibrant hues by forming covalent bonds with cellulose fibers, ideal for cotton-rich fabrics. Direct dyeing, while simpler, involves water-soluble dyes that attach physically to fibers, resulting in less wash durability and color brightness. Selecting the appropriate dyeing method ensures enhanced fabric performance and longevity in bath linen products.

Understanding Reactive Dyeing for Bath Linen

Reactive dyeing for bath linen involves a chemical reaction between the dye and cellulose fibers, creating strong covalent bonds that enhance colorfastness and durability. This method results in vibrant, long-lasting hues that resist fading and withstand frequent washing, essential for maintaining the quality of bath towels and robes. Compared to direct dyeing, reactive dyeing offers superior penetration and retention on cotton-based bath textiles, ensuring consistent and rich color performance.

Exploring Direct Dyeing in Bath Linen Production

Direct dyeing in bath linen production offers a cost-effective and simpler alternative to reactive dyeing, requiring fewer chemicals and less water. This method provides vibrant color retention on cotton fibers, although it generally yields lower wash fastness compared to reactive dyes. Manufacturers favor direct dyeing for its efficient process and suitability for mass production of bath towels and bathrobes with consistent hues.

Color Fastness: Reactive vs Direct Dyeing

Reactive dyeing offers superior color fastness for bath linen due to the chemical bonding formed between the dye and cotton fibers, resulting in enhanced resistance to washing, sunlight, and perspiration. Direct dyeing, relying on physical adsorption, generally exhibits lower color fastness, leading to faster fading and reduced durability in bath linens. This makes reactive dyes the preferred choice for vibrant, long-lasting coloration in high-quality bath textiles.

Durability and Wash Resistance Comparison

Reactive dyeing offers superior durability and wash resistance for bath linen due to covalent bonding between dye molecules and fabric fibers, resulting in vibrant colors that withstand repeated laundering. Direct dyeing, while simpler and cost-effective, generally exhibits lower fastness properties, leading to quicker fading and color loss after multiple washes. Fabrics treated with reactive dyes maintain their color intensity and fabric integrity longer, making them ideal for high-use bath linen products.

Environmental Impact of Reactive and Direct Dyeing

Reactive dyeing offers superior environmental benefits compared to direct dyeing, as it achieves higher color fixation rates, resulting in less dye runoff and reduced water pollution. Direct dyeing typically requires more water and salt additions, increasing effluent toxicity and treatment complexity in wastewater management. The selection of reactive dyes in bath linen production aligns with sustainable practices by minimizing chemical usage and lowering the ecological footprint of textile processing.

Cost Analysis: Reactive Dyeing vs Direct Dyeing

Reactive dyeing typically incurs higher costs due to the need for precise temperature control, longer fixation times, and the use of additional chemicals to achieve vibrant, long-lasting colors on bath linen. Direct dyeing offers a more cost-effective option with simpler application processes and lower energy consumption, albeit with generally less colorfastness and vibrancy. For manufacturers prioritizing budget efficiency in bath linen production, direct dyeing presents a viable alternative, while reactive dyeing remains preferable for premium, durable finishes.

Suitability for Different Bath Linen Fabrics

Reactive dyeing offers superior colorfastness and vibrant hues on natural fibers such as cotton and bamboo, making it highly suitable for bath linen like towels and bathrobes. Direct dyeing, while simpler and more cost-effective, performs best on cellulose fibers but may result in lower wash and light fastness, limiting its use in high-quality bath linen. Selecting the dyeing method depends on the fabric composition and desired durability, with reactive dyes preferred for premium, long-lasting bath textiles.

Consumer Preferences and Market Trends

Reactive dyeing in bath linen offers superior colorfastness and vibrant hues, driving consumer preference for long-lasting, high-quality towels. Direct dyeing, while cost-effective, often results in less durable colors, making it less favored in premium market segments. Growing demand for sustainable and vivid textiles has accelerated the adoption of reactive dyeing technologies across global bath linen markets.

Choosing the Best Dyeing Method for Bath Linen

Reactive dyeing offers superior color fastness and vibrancy for bath linen, ensuring long-lasting and fade-resistant fabrics. Direct dyeing, while more cost-effective, provides less durability and may result in colors that fade quickly with frequent washing. Selecting reactive dyeing for bath linens enhances fabric quality and maintains aesthetic appeal through repeated use and laundering.

Reactive dyeing vs Direct dyeing Infographic

productdif.com

productdif.com