Inverter compressors adjust their speed based on cooling demand, leading to higher energy efficiency and quieter operation compared to conventional compressors that run at a fixed speed. Conventional compressors cycle on and off frequently, causing more wear and inconsistent temperature control. Inverter technology extends appliance lifespan by reducing mechanical stress and maintaining a more stable environment.

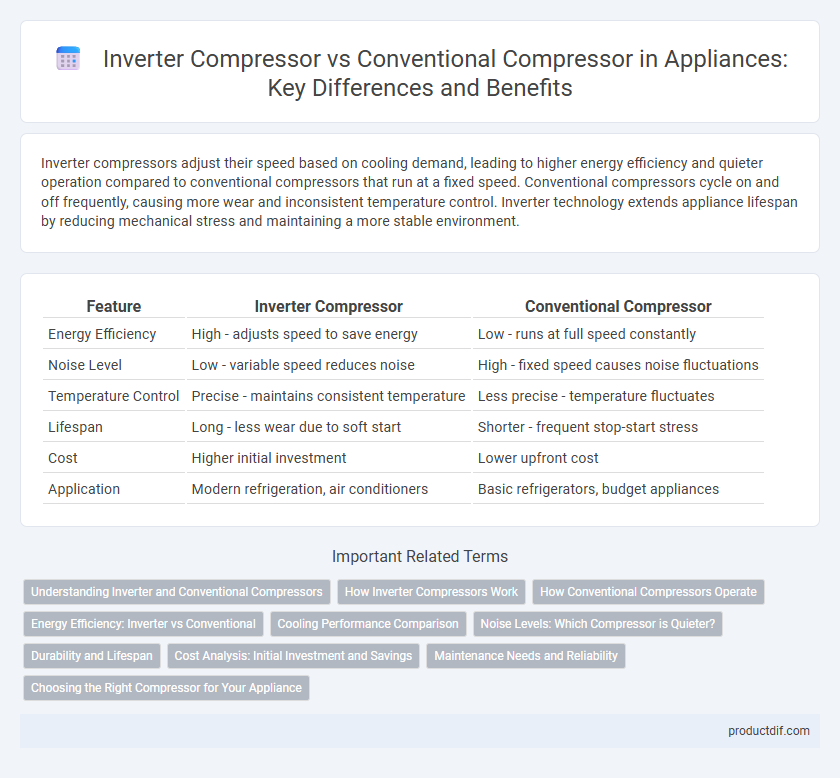

Table of Comparison

| Feature | Inverter Compressor | Conventional Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to save energy | Low - runs at full speed constantly |

| Noise Level | Low - variable speed reduces noise | High - fixed speed causes noise fluctuations |

| Temperature Control | Precise - maintains consistent temperature | Less precise - temperature fluctuates |

| Lifespan | Long - less wear due to soft start | Shorter - frequent stop-start stress |

| Cost | Higher initial investment | Lower upfront cost |

| Application | Modern refrigeration, air conditioners | Basic refrigerators, budget appliances |

Understanding Inverter and Conventional Compressors

Inverter compressors adjust their speed based on cooling demand, resulting in energy-efficient operation and precise temperature control, while conventional compressors operate at a fixed speed, cycling on and off to maintain temperature. This difference leads to inverter compressors offering quieter performance, reduced wear and tear, and lower electricity bills compared to conventional compressors. Understanding these operational mechanisms helps consumers choose appliances that balance performance, lifespan, and energy consumption effectively.

How Inverter Compressors Work

Inverter compressors regulate their speed based on cooling demand, enabling continuous adjustment of the motor's frequency and voltage for precise temperature control. This variable speed operation reduces energy consumption and minimizes wear and tear compared to conventional compressors that operate at a fixed speed, cycling on and off. By maintaining optimal performance, inverter compressors enhance appliance efficiency and durability, making them ideal for refrigerators and air conditioners.

How Conventional Compressors Operate

Conventional compressors operate by switching on and off to regulate temperature, causing fluctuating energy consumption and increased wear over time. This start-stop mechanism leads to less precise temperature control compared to inverter compressors. Their fixed-speed operation results in higher electricity usage and reduced efficiency in appliances like refrigerators and air conditioners.

Energy Efficiency: Inverter vs Conventional

Inverter compressors adjust their speed to match cooling demand, resulting in significant energy savings compared to conventional compressors that operate at a fixed speed with frequent on-off cycles. This variable speed operation reduces power consumption by up to 30-50%, enhancing overall appliance energy efficiency. Consequently, appliances with inverter compressors contribute to lower electricity bills and reduced environmental impact.

Cooling Performance Comparison

Inverter compressors adjust speed to maintain optimal cooling temperature, resulting in more consistent and efficient cooling performance compared to conventional compressors, which operate at fixed speeds causing temperature fluctuations. This variable speed technology in inverter compressors reduces energy consumption while enhancing cooling precision, leading to faster cooling and improved temperature stability. Conventional compressors typically cycle on and off, creating uneven cooling and increased wear, whereas inverter compressors ensure smoother operation and more reliable temperature control.

Noise Levels: Which Compressor is Quieter?

Inverter compressors operate at variable speeds, significantly reducing noise levels compared to conventional compressors that cycle on and off at full power. This continuous, steady operation minimizes vibration and sound, making inverter compressors ideal for quieter appliances such as refrigerators and air conditioners. Studies show inverter models can lower noise by up to 40%, enhancing user comfort in residential and commercial settings.

Durability and Lifespan

Inverter compressors offer superior durability and a longer lifespan compared to conventional compressors due to their ability to operate at variable speeds, reducing wear and tear on components. Conventional compressors run at a fixed speed, leading to more frequent starts and stops that increase mechanical stress and decrease overall lifespan. The advanced technology in inverter compressors ensures more consistent performance and energy efficiency, enhancing the appliance's reliability over time.

Cost Analysis: Initial Investment and Savings

Inverter compressors typically have a higher initial investment compared to conventional compressors due to advanced technology and components. However, inverter compressors offer significant energy savings by adjusting motor speed to demand, reducing electricity costs over time. The long-term operational savings often offset the upfront cost difference, making inverter compressors more cost-effective in energy-efficient appliances.

Maintenance Needs and Reliability

Inverter compressors require less frequent maintenance due to their ability to regulate speed and reduce wear on components, enhancing overall reliability compared to conventional compressors. Conventional compressors operate at fixed speeds, leading to more mechanical stress and higher chances of breakdowns, which increases maintenance needs. Energy-efficient inverter technology also extends compressor lifespan, reducing long-term repair costs and improving appliance durability.

Choosing the Right Compressor for Your Appliance

Selecting the right compressor for your appliance directly impacts energy efficiency and performance. Inverter compressors adjust speed based on cooling demand, reducing energy consumption and providing consistent temperature control, while conventional compressors operate at a fixed speed, leading to higher electricity usage and more wear and tear. For appliances like refrigerators and air conditioners, inverter compressors offer longer lifespan and quieter operation, making them ideal for energy-conscious consumers seeking reliability.

Inverter compressor vs Conventional compressor Infographic

productdif.com

productdif.com