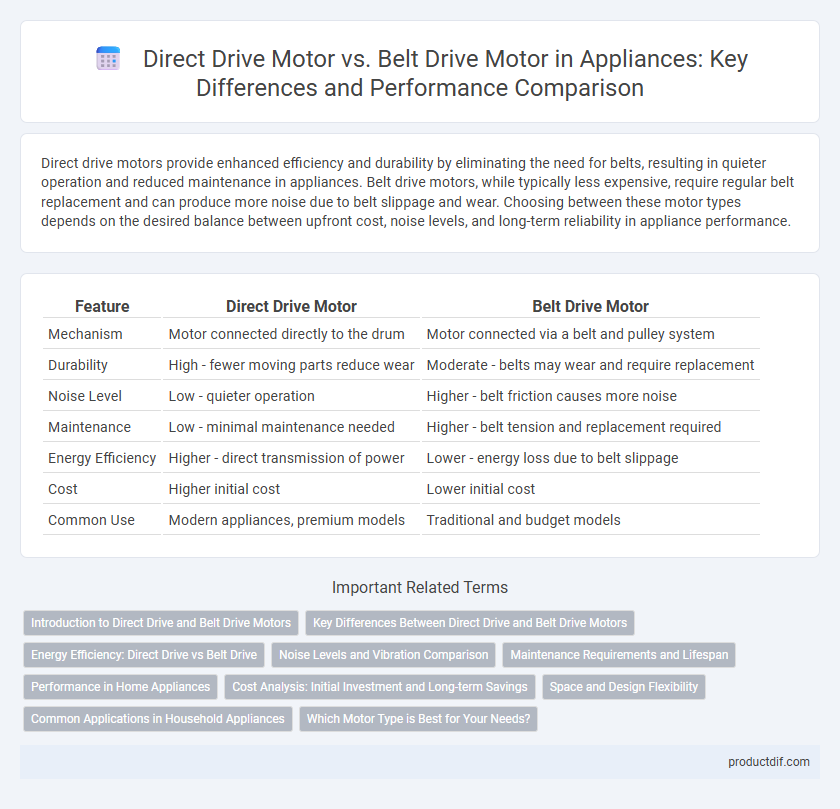

Direct drive motors provide enhanced efficiency and durability by eliminating the need for belts, resulting in quieter operation and reduced maintenance in appliances. Belt drive motors, while typically less expensive, require regular belt replacement and can produce more noise due to belt slippage and wear. Choosing between these motor types depends on the desired balance between upfront cost, noise levels, and long-term reliability in appliance performance.

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Mechanism | Motor connected directly to the drum | Motor connected via a belt and pulley system |

| Durability | High - fewer moving parts reduce wear | Moderate - belts may wear and require replacement |

| Noise Level | Low - quieter operation | Higher - belt friction causes more noise |

| Maintenance | Low - minimal maintenance needed | Higher - belt tension and replacement required |

| Energy Efficiency | Higher - direct transmission of power | Lower - energy loss due to belt slippage |

| Cost | Higher initial cost | Lower initial cost |

| Common Use | Modern appliances, premium models | Traditional and budget models |

Introduction to Direct Drive and Belt Drive Motors

Direct drive motors connect the motor shaft directly to the appliance component, eliminating the need for belts and pulleys, which enhances energy efficiency and reduces maintenance. Belt drive motors use a belt to transfer motion from the motor to the appliance drum or blade, allowing for smoother operation but requiring periodic belt replacement. In appliances like washing machines, direct drive motors are valued for their durability and quiet performance, while belt drive motors are often found in budget-friendly models due to their lower initial cost.

Key Differences Between Direct Drive and Belt Drive Motors

Direct drive motors connect the motor directly to the appliance component, offering higher efficiency, reduced noise, and longer durability due to fewer moving parts. Belt drive motors use a belt to transfer motion from the motor to the appliance, resulting in more vibration and wear over time but often providing quieter operation initially. The key differences lie in maintenance requirements, noise levels, and energy efficiency, with direct drive motors favored in premium appliances for their reliability and performance.

Energy Efficiency: Direct Drive vs Belt Drive

Direct drive motors in appliances offer superior energy efficiency by eliminating the energy loss typically caused by belt friction and slippage found in belt drive motors. This direct connection ensures more power is transferred from the motor to the appliance, reducing electricity consumption and operational costs. Consequently, appliances with direct drive motors often achieve higher efficiency ratings and longer lifespan compared to those using belt drive systems.

Noise Levels and Vibration Comparison

Direct drive motors in appliances generate significantly lower noise levels and vibrations compared to belt drive motors, as they eliminate the need for belts and pulleys that typically cause friction and rattling. This results in smoother operation and reduced wear and tear, enhancing overall appliance longevity and user comfort. Noise measurements indicate direct drive systems often operate under 50 decibels, whereas belt drive systems can exceed 60 decibels due to belt squealing and motor vibration.

Maintenance Requirements and Lifespan

Direct drive motors require minimal maintenance due to fewer moving parts and the absence of belts, significantly reducing wear and tear over time. Belt drive motors demand regular belt inspections and replacements to maintain optimal performance, increasing maintenance frequency. The lifespan of direct drive motors typically exceeds that of belt drive motors by several years, owing to enhanced durability and reduced mechanical stress.

Performance in Home Appliances

Direct drive motors in home appliances offer superior performance by eliminating belts, reducing noise, and enhancing energy efficiency through direct connection to the drum. Belt drive motors, while generally less expensive, may suffer from wear and tear, leading to increased maintenance and reduced operational lifespan. Appliances with direct drive motors typically demonstrate improved reliability, smoother operation, and better load handling, making them ideal for high-performance washing machines and dryers.

Cost Analysis: Initial Investment and Long-term Savings

Direct drive motors typically have a higher initial investment due to advanced technology and fewer moving parts, resulting in lower maintenance costs and increased durability. Belt drive motors often require cheaper upfront costs but incur ongoing expenses from belt replacements, tension adjustments, and greater wear and tear. Over the appliance lifespan, direct drive motors offer significant long-term savings through reduced energy consumption and decreased repair frequency.

Space and Design Flexibility

Direct drive motors save significant space by eliminating the need for belts and pulleys, allowing for a more compact appliance design. This space efficiency enhances design flexibility, enabling manufacturers to create sleeker, more modern appliances that maximize internal capacity. Belt drive motors require additional room for belts and tensioners, which can limit innovative design possibilities and reduce usable interior space.

Common Applications in Household Appliances

Direct drive motors are commonly used in washing machines and dishwashers due to their efficiency, reduced noise, and longer lifespan. Belt drive motors are often found in vacuum cleaners and older model dryers, where cost-effectiveness and easier motor replacement are prioritized. Selecting the appropriate motor type directly impacts appliance performance and maintenance requirements in household settings.

Which Motor Type is Best for Your Needs?

Direct drive motors offer higher efficiency, reduced noise, and longer lifespan due to fewer moving parts, making them ideal for energy-conscious users seeking low maintenance. Belt drive motors provide smoother operation and easier repair options, often found in budget-friendly appliances requiring occasional maintenance. Choosing between the two depends on priorities like durability, noise levels, and overall appliance cost.

Direct Drive Motor vs Belt Drive Motor Infographic

productdif.com

productdif.com